100% Original Factory Welded Chains - Conveyor Chains, including M, FV, FVT, MT Series, also with Attachments, and Double Pith Conveyor Chians – GOODLUCK

100% Original Factory Welded Chains - Conveyor Chains, including M, FV, FVT, MT Series, also with Attachments, and Double Pith Conveyor Chians – GOODLUCK Detail:

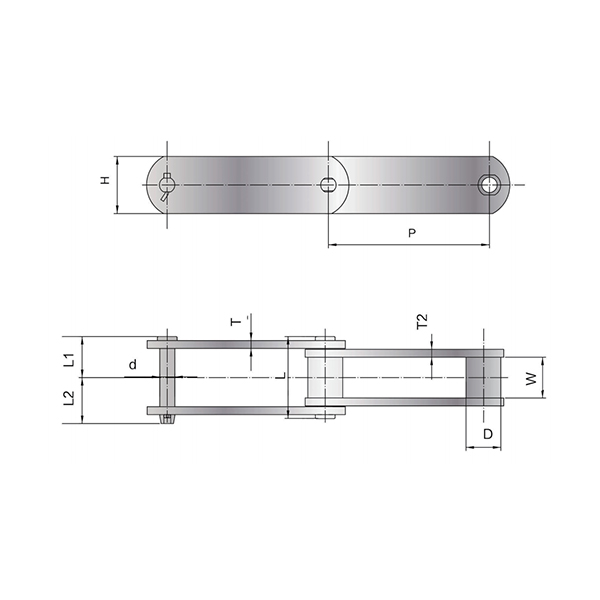

M SERIES CONVEYOR CHAINS AND ATTACHMENTS

|

GL Chain No. |

Pitch |

Roller dia. |

Inside width |

Height of plate |

Pin dia. |

Length of Pin |

Ultimate tensie strength |

||||||||

|

P |

d1(max) |

d3(max) |

b2(max) |

d4(max) |

b1(max) |

h2(max) |

d2(max) |

L |

Q |

||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

||||||

|

M20 |

50 |

63 |

80 |

100 |

125 |

160 |

25 |

35 |

3.50 |

12.50 |

15 |

19 |

6.00 |

35 |

20 |

|

M28 |

63 |

80 |

100 |

125 |

160 |

200 |

30 |

40 |

4.00 |

15.00 |

17 |

21 |

7.00 |

40 |

28 |

|

M40 |

80 |

100 |

125 |

160 |

200 |

250 |

36 |

45 |

4.50 |

18.00 |

19 |

26 |

8.50 |

45 |

40 |

|

M56 |

80 |

100 |

125 |

160 |

200 |

250 |

42 |

55 |

5.00 |

21.00 |

23 |

31 |

10.00 |

52 |

56 |

|

M80 |

100 |

125 |

160 |

200 |

250 |

315 |

50 |

65 |

6.00 |

25.00 |

27 |

36 |

12.00 |

62 |

80 |

|

M112 |

125 |

160 |

200 |

250 |

315 |

400 |

60 |

75 |

7.00 |

30.00 |

31 |

41 |

15.00 |

73 |

112 |

|

M160 |

160 |

200 |

250 |

315 |

400 |

500 |

70 |

90 |

8.50 |

36.00 |

36 |

51 |

18.00 |

85 |

160 |

|

M224 |

200 |

250 |

315 |

400 |

500 |

630 |

85 |

105 |

10.00 |

42.00 |

42 |

62 |

21.00 |

96 |

224 |

|

M315 |

200 |

250 |

315 |

400 |

500 |

630 |

100 |

125 |

12.00 |

50.00 |

47 |

72 |

25.00 |

112 |

315 |

|

M450 |

250 |

315 |

400 |

500 |

630 |

800 |

120 |

150 |

14.00 |

60.00 |

55 |

82 |

30.00 |

135 |

450 |

|

M630 |

250 |

315 |

400 |

500 |

630 |

800 |

140 |

175 |

16.00 |

70.00 |

65 |

105 |

36.00 |

154 |

630 |

|

M900 |

315 |

400 |

500 |

630 |

800 |

1000 |

170 |

210 |

18.00 |

85.00 |

76 |

123 |

44.00 |

180 |

900 |

|

2915-10 |

76.20 |

38.40 |

- |

- |

- |

24.40 |

28.70 |

11.20 |

58.90 |

48.95 |

|||||

|

2915-20 |

101.60 |

38.40 |

- |

- |

- |

24.40 |

28.70 |

11.20 |

58.90 |

48.95 |

|||||

|

2915-30 |

101.60 |

51.10 |

- |

一 |

一 |

27.70 |

31.80 |

11.20 |

63.80 |

62.30 |

|||||

|

2915-40 |

101.60 |

38.40 |

- |

- |

- |

21.10 |

31.80 |

12.78 |

64.30 |

71.20 |

|||||

|

2915-50 |

101.60 |

57.40 |

- |

- |

- |

32.00 |

38.10 |

15.95 |

90.90 |

106.80 |

|||||

|

2915-60 |

152.40 |

51.10 |

- |

一 |

一 |

27.40 |

31.80 |

11.20 |

69.10 |

66.75 |

|||||

|

2915-70 |

152.40 |

63.80 |

- |

- |

- |

30.50 |

38.10 |

14.38 |

76.70 |

89.00 |

|||||

|

2915-80 |

152.40 |

51.10 |

- |

- |

- |

32.00 |

38.10 |

15.95 |

87.60 |

102.35 |

|||||

|

2915-90 |

152.40 |

76.50 |

— |

— |

— |

33.83 |

50.80 |

19.13 |

97.80 |

146.85 |

|||||

|

GL Chain No. |

“K”Type |

“H”Type Deep Link |

|||||||||

|

d8 |

h4 |

f |

b9 |

孑L心距 Distance of holes |

H6 |

||||||

|

mm |

mm |

mm |

mm |

P |

g |

P |

g |

P |

g |

mm |

|

|

M20 |

6.60 |

16 |

54 |

84 |

63 |

20 |

80 |

35 |

100 |

50 |

16.00 |

|

M28 |

9.00 |

20 |

64 |

100 |

80 |

25 |

100 |

40 |

125 |

65 |

20.00 |

|

M40 |

9.00 |

25 |

70 |

112 |

80 |

20 |

100 |

40 |

125 |

65 |

22.50 |

|

M56 |

11.00 |

30 |

88 |

140 |

100 |

25 |

125 |

50 |

160 |

85 |

30.00 |

|

M80 |

11.00 |

35 |

96 |

160 |

125 |

50 |

160 |

85 |

200 |

125 |

32.50 |

|

M112 |

14.00 |

40 |

110 |

184 |

125 |

35 |

160 |

65 |

200 |

100 |

40.00 |

|

M160 |

14.00 |

45 |

124 |

200 |

160 |

50 |

200 |

85 |

250 |

145 |

45.00 |

|

M224 |

18.00 |

55 |

140 |

228 |

200 |

65 |

250 |

125 |

315 |

190 |

60.00 |

|

M315 |

18.00 |

65 |

160 |

250 |

200 |

50 |

250 |

100 |

315 |

155 |

65.00 |

|

M450 |

18.00 |

75 |

180 |

280 |

225 |

85 |

315 |

155 |

400 |

240 |

80.00 |

|

M630 |

24.00 |

90 |

230 |

380 |

315 |

100 |

400 |

190 |

500 |

300 |

90.00 |

|

M900 |

30.00 |

110 |

280 |

480 |

315 |

65 |

400 |

155 |

500 |

240 |

120.00 |

FV SERIES CONVEYOR CHAINS

|

GL Chain No. |

Pitch |

Inside width |

Plate depth |

Pin dia. |

Barrel dia. |

Plate Thickness |

Roller dimension |

Pin Length |

Ultimate tensie strength |

||||||||

|

P |

b1 |

h2 |

d2 |

d3 |

T |

d4 |

d1 |

d5 |

d6 |

L |

Lc |

Q |

|||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

|||||

|

FV40 |

40 |

50 |

63 |

80 |

100 |

18 |

26 |

10 |

15 |

3 |

20 |

32 |

40 |

48 |

37 |

39.50 |

40 |

|

FV63 |

63 |

80 |

100 |

125 |

160 |

22 |

30 |

12 |

18 |

4 |

26 |

40 |

50 |

60 |

46 |

50.50 |

63 |

|

FV90 |

63 |

100 |

125 |

160 |

200 |

25 |

35 |

14 |

20 |

5 |

30 |

48 |

63 |

73 |

53 |

57.50 |

90 |

|

FV112 |

100 |

125 |

160 |

200 |

250 |

30 |

40 |

16 |

22 |

6 |

32 |

55 |

72 |

87 |

63 |

67.50 |

112 |

|

FV140 |

100 |

125 |

160 |

200 |

250 |

35 |

45 |

18 |

26 |

6 |

36 |

60 |

80 |

95 |

68 |

74.00 |

140 |

|

FV180 |

125 |

160 |

200 |

250 |

315 |

45 |

50 |

20 |

30 |

8 |

42 |

70 |

100 |

120 |

86 |

93.00 |

180 |

|

FV250 |

160 |

200 |

250 |

315 |

400 |

55 |

60 |

26 |

36 |

8 |

50 |

80 |

125 |

145 |

98 |

106.00 |

250 |

|

FV315 |

160 |

200 |

250 |

315 |

400 |

65 |

70 |

30 |

42 |

10 |

60 |

90 |

140 |

170 |

117 |

125.00 |

315 |

|

FV400 |

160 |

200 |

250 |

315 |

400 |

70 |

70 |

32 |

44 |

12 |

60 |

100 |

150 |

185 |

131 |

141.00 |

400 |

|

FV500 |

200 |

250 |

315 |

400 |

500 |

80 |

80 |

36 |

50 |

12 |

70 |

110 |

160 |

195 |

141 |

151.00 |

500 |

|

FV630 |

200 |

250 |

315 |

400 |

500 |

90 |

100 |

42 |

56 |

12 |

80 |

120 |

170 |

210 |

153 |

163.00 |

630 |

FVT/MT SERIES CONVEYOR CHAINS

|

GL Chain No. |

Pitch |

Inside width |

Roller dia. |

Pin dia. |

Barrel dia. |

Plate Thickness |

Plate depth |

Pin Length |

Ultimate tensie strength |

||||||

|

P |

b1 |

d1 |

d2 |

d3 |

T |

hi |

h2 |

L |

Q |

||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

||||||

|

FVT40 |

40 |

63 |

100 |

- |

- |

- |

18 |

32 |

10 |

15 |

3 |

35 |

22 |

37 |

40 |

|

FVT63 |

63 |

100 |

125 |

160 |

- |

- |

2 |

40 |

12 |

18 |

4 |

40 |

25 |

46 |

63 |

|

FVT90 |

63 |

100 |

125 |

160 |

200 |

250 |

25 |

48 |

14 |

20 |

5 |

45 |

27.50 |

53 |

90 |

|

FVT112 |

100 |

125 |

160 |

200 |

250 |

一 |

30 |

55 |

16 |

22 |

6 |

50 |

30 |

63 |

112 |

|

FVT140 |

100 |

125 |

160 |

200 |

250 |

315 |

35 |

60 |

18 |

26 |

6 |

60 |

37.50 |

68 |

140 |

|

FVT180 |

125 |

160 |

200 |

250 |

315 |

400 |

45 |

70 |

20 |

30 |

8 |

70 |

45 |

86 |

180 |

|

FVT250 |

125 |

160 |

200 |

250 |

315 |

400 |

55 |

80 |

26 |

36 |

8 |

80 |

50 |

98 |

250 |

|

FVT315 |

160 |

200 |

250 |

315 |

400 |

- |

65 |

90 |

30 |

42 |

10 |

90 |

55 |

117 |

315 |

|

FVT400 |

160 |

200 |

250 |

315 |

400 |

- |

70 |

100 |

32 |

44 |

12 |

90 |

55 |

131 |

400 |

|

FVT500 |

160 |

200 |

250 |

315 |

400 |

500 |

80 |

110 |

36 |

50 |

12 |

100 |

60 |

141 |

500 |

|

FVT630 |

200 |

250 |

315 |

400 |

500 |

- |

90 |

120 |

42 |

56 |

12 |

120 |

70 |

153 |

630 |

MT SERIES CONVEYOR CHAINS

|

GL Chain No. |

Pitch |

Inside width |

Roller dia. |

Pin dia. |

Barrel dia. |

Plate Thickness |

Plate depth |

Pin Length |

Ultimate tensie strength |

|||||

|

P |

b1 |

d1 |

d2 |

d3 |

T |

hi |

h2 |

L |

Q |

|||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

|||||

|

MT20 |

40 |

50 |

63 |

80 |

100 |

16 |

25 |

6 |

9 |

2.50 |

25 |

16 |

35 |

20 |

|

MT28 |

50 |

63 |

80 |

100 |

125 |

18 |

30 |

7 |

10 |

3 |

30 |

20 |

40 |

28 |

|

MT40 |

63 |

80 |

100 |

125 |

160 |

20 |

36 |

8.50 |

12.50 |

3.50 |

35 |

22.50 |

45 |

40 |

|

MT56 |

63 |

80 |

100 |

125 |

160 |

24 |

42 |

10 |

15 |

4 |

45 |

30 |

52 |

56 |

|

MT80 |

80 |

100 |

125 |

160 |

200 |

28 |

50 |

12 |

18 |

5 |

50 |

32.50 |

62 |

80 |

|

MT112 |

80 |

100 |

125 |

160 |

200 |

32 |

60 |

15 |

21 |

6 |

60 |

40 |

73 |

112 |

|

MT160 |

100 |

125 |

160 |

200 |

250 |

37 |

70 |

18 |

25 |

7 |

70 |

45 |

85 |

160 |

|

MT224 |

125 |

160 |

200 |

250 |

315 |

43 |

85 |

21 |

30 |

8 |

90 |

60 |

98 |

224 |

|

MT315 |

160 |

200 |

250 |

315 |

400 |

48 |

100 |

25 |

36 |

10 |

100 |

65 |

112 |

315 |

|

MT450 |

200 |

250 |

315 |

400 |

500 |

56 |

120 |

30 |

42 |

12 |

120 |

80 |

135 |

450 |

|

MT630 |

- |

250 |

315 |

400 |

500 |

66 |

140 |

36 |

50 |

14 |

140 |

90 |

154 |

630 |

|

MT900 |

- |

250 |

315 |

400 |

500 |

78 |

170 |

44 |

60 |

16 |

180 |

120 |

180 |

900 |

DOUBLE PITCH CONVEYOR ROLLER CHAINS

|

GL Chain No. |

Pitch |

Roller dia. |

Inside width |

Pin dia. |

Plate depth |

Ultimate tensie strength |

Weight per meter |

|

|

iso |

ANSI |

P |

d1 |

b1 |

d2 |

hi |

Q |

q |

|

mm |

mm |

mm |

mm |

mm |

kN |

kg/m |

||

|

C208A |

C2040 |

25.40 |

7.92 |

7.85 |

3.98 |

12.07 |

13.90 |

0.50 |

|

C208AL |

C2042 |

15.88 |

0.84 |

|||||

|

C208B |

A |

25.40 |

8.51 |

7.75 |

4.45 |

11.81 |

17.80 |

0.55 |

|

C208BL |

A |

15.88 |

0.89 |

|||||

|

C210A |

C2050 |

31.75 |

10.16 |

9.40 |

5.09 |

15.09 |

21.80 |

0.73 |

|

C210AL |

C2052 |

19.05 |

1.27 |

|||||

|

C212A |

C2060 |

38.10 |

11.91 |

H o C7 |

5.96 |

18.10 |

31.30 |

1.12 |

|

C212AL |

C2062 |

22.23 |

1 ^.0 r |

1.61 |

||||

|

C212AH |

C2060H |

38.10 |

11.91 |

12.57 |

5.96 |

18.10 |

31.30 |

1.44 |

|

C212AHL |

C2062H |

22.23 |

2.07 |

|||||

|

C216A |

C2080 |

50.80 |

15.88 |

15.75 |

7.94 |

24.13 |

55.60 |

2.08 |

|

C216AL |

C2082 |

28.58 |

3.12 |

|||||

|

C216AH |

C2080H |

50.80 |

15.88 |

15.75 |

7.94 |

24.13 |

55.60 |

2.54 |

|

C216AHL |

C2082H |

28.58 |

3.58 |

|||||

|

C220A |

C2100 |

63.50 |

19.05 |

18.90 |

9.54 |

30.17 |

87.00 |

3.01 |

|

C220AL |

C2102 |

39.67 |

4.83 |

|||||

|

C220AH |

C2100H |

63.50 |

19.05 |

18.90 |

9.54 |

30.17 |

87.00 |

3.56 |

|

C220AHL |

C2102H |

39.67 |

5.38 |

|||||

|

C224A |

C2120 |

76.20 |

22.23 |

25.22 |

11.11 |

36.20 |

125.00 |

4.66 |

|

C224AL |

C2122 |

44.45 |

7.66 |

|||||

|

C224AH |

C2120H |

76.20 |

22.23 |

25.22 |

11.11 |

36.20 |

125.00 |

5.26 |

|

C224AHL |

C2122H |

44.45 |

8.26 |

|||||

|

C232A |

C2160 |

101.60 |

28.58 |

31.75 |

14.29 |

48.26 |

223.00 |

8.15 |

|

C232AL |

C2162 |

57.15 |

13.00 |

|||||

|

C232AH |

C2160H |

101.60 |

25.58 |

31.75 |

14.29 |

48.26 |

223.00 |

9.06 |

|

C232AHL |

C2162H |

57.15 |

12.77 |

|||||

Conveyor chains are used in a variety of applications as diverse as food service and automotive parts. Historically, the automotive industry has been a major user of this type of transportation of heavy items between various stations within a warehouse or production facility. The sturdy chain conveyor systems present a cost-effective and reliable method for boosting productivity by keeping items off of the factory floor. Conveyor chains come in a variety of sizes, such as Standard Roller Chain, Double Pitch Roller Chain, Case Conveyor Chain, Stainless Steel Conveyor Chains – C Type, and Nickel Plated ANSI Conveyor Chains.

Product detail pictures:

Related Product Guide:

Well-run products, skilled income group, and better after-sales products and services; We have been also a unified massive family, all people stick with the business price "unification, dedication, tolerance" for 100% Original Factory Welded Chains - Conveyor Chains, including M, FV, FVT, MT Series, also with Attachments, and Double Pith Conveyor Chians – GOODLUCK , The product will supply to all over the world, such as: Malaysia, Moldova, Kuwait, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.