2021 Good Quality Spline Shaft Coupling - TGL (GF) Couplings,Curved Gear Couplings with Yellow Nylon Sleeve – GOODLUCK

2021 Good Quality Spline Shaft Coupling - TGL (GF) Couplings,Curved Gear Couplings with Yellow Nylon Sleeve – GOODLUCK Detail:

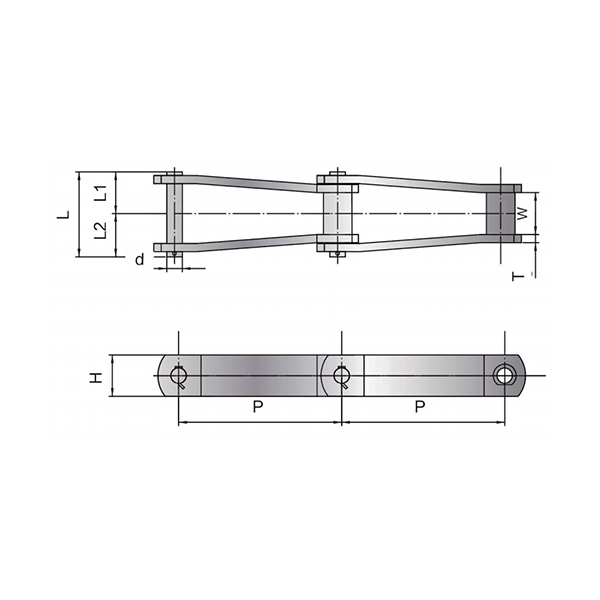

Curved gear coupling

TGL Series (GF-SERIES)

Product features

• Double section curved surface coupling

• Widely used in various fields of machinery and hydraulics

• Non maintenance of nylon and steel material

• Compensation for axial, radial and angular errors

• The axial insert assembly is very convenient

• The product hole tolerance is H7 according Io the ISO standard, and the tolerance of keyway width is in accordance with the standard, DIN6885/1byJS9, Another inch and the cone hole

• For installation size, see the table below:

|

Model |

Finished bore dl , d2

|

Dimension(mm) |

Coupling Weightwith Max, Aperture |

RatedTorque |

|||||||||||

|

General |

Lengthened |

Premachlned Bore |

Max , aperture |

L1,L2 |

L0 |

L |

M,N |

E |

L1,L2 Max |

D1 |

D |

Weight of Nylon-seelve |

Total Weight |

N.m |

|

|

TGL-14 |

TGL-14-L |

- |

Customers could order finished |

14 |

23 |

50 |

37 |

6.5 |

4 |

40 |

40 |

24 |

0.02 |

0.14 |

10 |

|

TGL-19 |

TGL-19-L |

- |

19 |

25 |

54 |

37 |

8.5 |

4 |

40 |

48 |

30 |

0.03 |

0.21 |

16 |

|

|

TGL-24 |

TGL-24-L |

- |

24 |

26 |

56 |

41 |

7.5 |

4 |

50 |

52 |

36 |

0.04 |

0.25 |

20 |

|

|

TGL-28 |

TGL-28-L |

- |

28 |

40 |

84 |

46 |

19 |

4 |

55 |

66 |

44 |

0.07 |

0.62 |

45 |

|

|

TGL-32 |

TGL-32-L |

- |

32 |

40 |

84 |

48 |

18 |

4 |

55 |

76 |

50 |

0.09 |

0.83 |

60 |

|

|

TGL-38 |

TGL-38-L |

- |

38 |

40 |

84 |

48 |

18 |

4 |

60 |

83 |

58 |

0J1 |

1.04 |

80 |

|

|

TGL-42 |

TGL-42-L |

- |

42 |

42 |

88 |

50 |

19 |

4 |

60 |

92 |

65 |

0.14 |

1.41 |

100 |

|

|

TGL-48 |

TGL-48-L |

- |

48 |

50 |

104 |

50 |

27 |

4 |

60 |

92 |

67 |

0.16 |

1.43 |

140 |

|

|

TGL-55 |

TGL-55-L |

- |

55 |

52 |

108 |

58 |

25 |

4 |

65 |

114 |

82 |

0.26 |

2.50 |

240 |

|

|

TGL-65 |

TGL-65-L |

- |

65 |

55 |

114 |

68 |

23 |

4 |

70 |

132 |

95 |

0.39 |

3.58 |

380 |

|

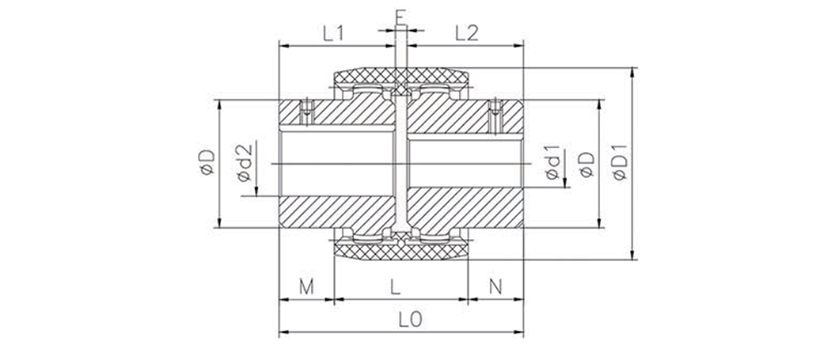

The GF Coupling consists of two steel hubs with

external crowned and barrelled gear teeth, Oxidation blacked protection, connected by a synthetic resin sleeve. The

sleeve is manufactured from high molecular weight polyamide,

thermally conditioned and impregnated with solid lubricant to

provide a long maintenance-free life. This sleeve has high resistance

to atmospheric humidity and an operating temperature range of

–20˚C to +80˚C with ability to withstand 120˚C for short durations.

The GF Series Couplings are made with two hub lengths; a standard hub suitable for most applications, and a longer hub.

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for 2021 Good Quality Spline Shaft Coupling - TGL (GF) Couplings,Curved Gear Couplings with Yellow Nylon Sleeve – GOODLUCK , The product will supply to all over the world, such as: Miami, Brisbane, Hamburg, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

){%XYQC.png)