China wholesale Taper Bore Sprockets - Double Pitch Sprockets per Asian Standard – GOODLUCK

China wholesale Taper Bore Sprockets - Double Pitch Sprockets per Asian Standard – GOODLUCK Detail:

NK2040SB

| SPROCKETS | mm |

| Tooth width (T) | 7.2 |

| CHAIN | mm |

| Pitch (P) | 25.4 |

| Internal width | 7.95 |

| Roller Φ (Dr) | 7.95 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

Wt kg |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK2040SB |

6 1/2 |

59 |

54.66 |

13 |

15 |

20 |

35 |

22 |

0.20 |

C45 Solid |

|

7 1/2 |

67 |

62.45 |

13 |

15 |

25 |

43 |

22 |

0.30 |

||

|

8 1/2 |

76 |

70.31 |

13 |

15 |

32 |

52 |

22 |

0.42 |

||

|

9 1/2 |

84 |

78.23 |

13 |

15 |

38 |

60 |

25 |

0.61 |

||

|

10 1/2 |

92 |

86.17 |

14 |

16 |

46 |

69 |

25 |

0.82 |

||

|

11 1/2 |

100 |

94.15 |

14 |

16 |

51 |

77 |

25 |

0.98 |

||

|

12 1/2 |

108 |

102.14 |

14 |

16 |

42 |

63 |

25 |

0.83 |

||

NK 2050SB

| SPROCKETS | mm |

| Tooth width (T) | 8.7 |

| CHAIN | mm |

| Pitch (P) | 31.75 |

| Internal width | 9.53 |

| Roller Φ (Dr) | 10.16 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

Wt kg |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK2050SB |

6 1/2 |

74 |

68.32 |

14 |

16 |

25 |

44 |

25 |

038 |

C45 Solid |

|

7 1/2 |

84 |

78.06 |

14 |

16 |

32 |

54 |

25 |

0.55 |

||

|

8 1/2 |

94 |

87.89 |

14 |

16 |

45 |

65 |

25 |

0-76 |

||

|

9 1/2 |

105 |

97.78 |

14 |

16 |

48 |

73 |

28 |

1-06 |

||

|

10 1/2 |

115 |

107,72 |

14 |

16 |

48 |

73 |

28 |

1.16 |

||

|

11 1/2 |

125 |

117.68 |

16 |

18 |

48 |

73 |

28 |

1.27 |

||

|

12 1/2 |

135 |

127.67 |

16 |

18 |

48 |

73 |

28 |

1.40 |

||

NK 2060SB

| SPROCKETS | mm |

| Tooth width (T) | 11.7 |

| CHAIN | mm |

| Pitch (P) | 38.10 |

| Internal width | 12.70 |

| Roller Φ (Dr) | 11.91 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt kg |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK2060SB |

6 1/2 |

88 |

81.98 |

14 |

16 |

32 |

53 |

32 |

0.73 |

C45 Solid |

|

7 1/2 |

101 |

93.67 |

16 |

18 |

45 |

66 |

32 |

1.05 |

||

|

8 1/2 |

113 |

105.47 |

16 |

18 |

48 |

73 |

32 |

133 |

||

|

9 1/2 |

126 |

117.34 |

16 |

18 |

55 |

83 |

40 |

203 |

||

|

10 1/2 |

138 |

129.26 |

16 |

18 |

55 |

83 |

40 |

2.23 |

||

|

11 1/2 |

150 |

141.22 |

16 |

18 |

55 |

80 |

45 |

256 |

||

|

12 1/2 |

162 |

153.20 |

16 |

18 |

55 |

80 |

45 |

281 |

||

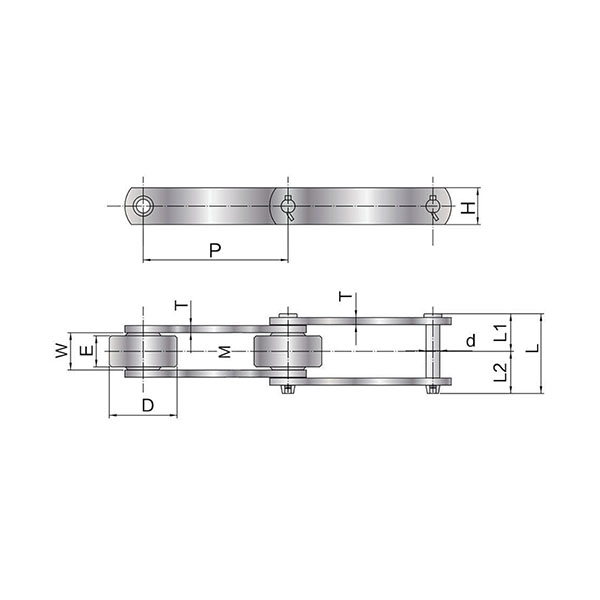

Double pitch conveyor chain sprockets are often are ideal for saving on space and have a longer wear life than standard sprockets. Suitable for long pitch chain, double pitch sprockets possess more teeth than a standard sprocket of the same pitch circle diameter and distribute wear evenly across the teeth. If your conveyor chain is compatible, double pitch sprockets are definitely worth considering.

Sprockets for double pitch roller chains are available in a single or double-toothed design. Single-toothed sprockets for double pitch roller chains have the same behaviour as standard sprockets for roller chains according to DIN 8187 (ISO 606). Due to the larger chain pitch of double pitch roller chains it is possible to increase durability by toothing modifications.

Standard roller type sprockets are the same outside diameter and width as the single-pitch equivalent just with a different tooth profile to allow proper seating of the chain. On even tooth-counts, these sprockets only engage with the chain on every other tooth because there are two teeth per pitch. On odd tooth counts, any given tooth is engaged only on every other revolution which of course increases the sprocket life.

Product detail pictures:

Related Product Guide:

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for China wholesale Taper Bore Sprockets - Double Pitch Sprockets per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: UK, Germany, Belarus, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.