Factory made hot-sale Sleeve Coupling - Weld-On-Hubs, Type W, WH,WM per C20 Material – GOODLUCK

Factory made hot-sale Sleeve Coupling - Weld-On-Hubs, Type W, WH,WM per C20 Material – GOODLUCK Detail:

Weld-on-Hubs

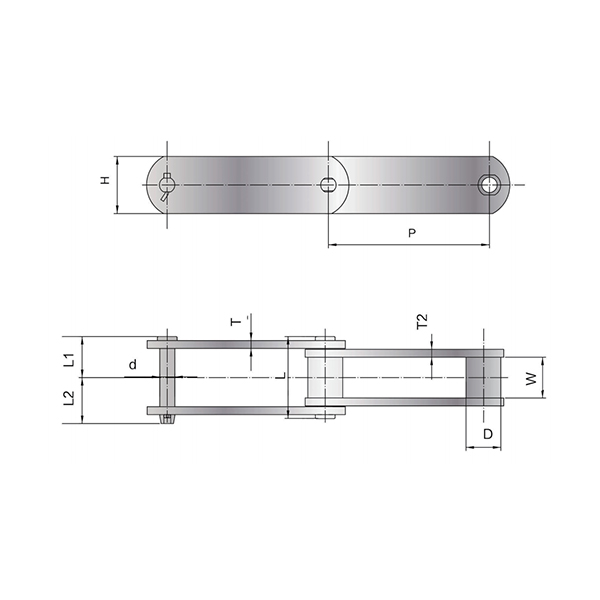

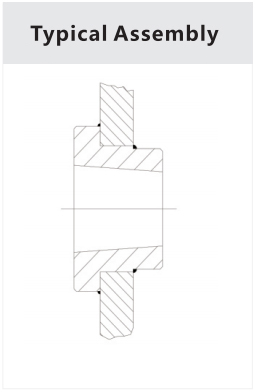

Taper Bore Weld-on-Hubs are made out of steel,drilled, tapped and taper bored to receive standard Taper Bushes. The extended flange provides a convenient means of welding hubs into fan rotors, steel pulleys, plate sprockets, impellers, agitators and many other devices which must be firmly fastened the shaft. Weld-on-Hubs are easy to install and entirely suitable for use where severe operating conditions are met. Tightening the xcrews contracts the bore of the bush, thereby looking it to the shaft with the equivalent of press fit .This type of construction eliminates mounting difficulties, it also prevents loosening and wear on the hub during operation. Weld-on-Hubs are manufactured to complemen Taper Bush range and include W,WG,WH, WHG, WM and WMG Taper Bore Hubs. All are manufactured to world standards using C20 steel.

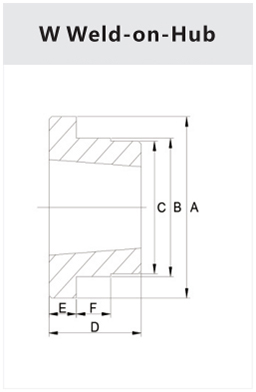

W Weld-on-Hubs

|

Hub |

Bush Size |

A |

B |

C |

D |

E |

F |

Fl |

X |

|

W12 |

1215 |

73.03 |

63.50 |

62.71 |

38.10 |

15.88 |

9.53 |

- |

- |

|

W16 |

1615 |

82.55 |

73.03 |

72.24 |

38.10 |

15388 |

9.53 |

- |

- |

|

W25 |

2517 |

127.00 |

111.13 |

110.34 |

44.45 |

19.05 |

12.70 |

- |

- |

|

WG30 |

3030 |

149.86 |

133.35 |

132.56 |

76.20 |

25.40 |

19.05 |

23 |

23 |

|

WG35 |

3535 |

184.15 |

158.75 |

157.96 |

88.90 |

31.75 |

25.04 |

30 |

30 |

|

WG40 |

4040 |

225.43 |

169.85 |

196.06 |

101.60 |

31.75 |

31.75 |

34 |

34 |

|

WG45 |

4545 |

254.00 |

222.25 |

221.46 |

114.30 |

38.10 |

38.10 |

38 |

38 |

|

WG50 |

5050 |

267.00 |

241.00 |

240.25 |

127.00 |

38.10 |

38.10 |

42 |

42 |

|

WG60 |

6060 |

375.00 |

343.00 |

342.00 |

127.00 |

38.10 |

38.10 |

42 |

42 |

|

WG70 |

7060 |

425.00 |

375.00 |

374.00 |

153.00 |

51.00 |

51.00 |

51 |

51 |

|

WG80 |

8065 |

445.00 |

349.0 |

393.00 |

165.00 |

51.00 |

51.00 |

55 |

55 |

|

WG100 |

10085 |

559.00 |

495.00 |

494.00 |

216.00 |

51.00 |

51.00 |

72 |

72 |

“G”: natation represents welding relief

Weld-on-Hubs

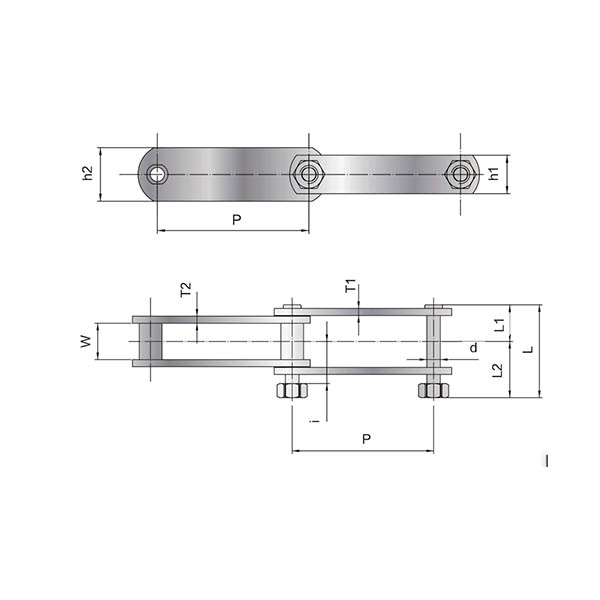

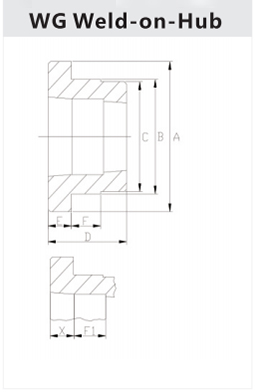

WH Weld-on-Hubs

|

Hub Reference |

Bush Size |

A |

B |

C |

D |

E |

F |

Fl X |

|

|

WH12 |

1210 |

70 |

65 |

64.5 |

25 |

9 |

10 |

- |

- |

|

WH16-1 |

1610 |

80 |

75 |

74.5 |

25 |

9 |

10 |

- |

- |

|

WH20 |

2012 |

95 |

90 |

89.5 |

32 |

12 |

12 |

- |

- |

|

WH25 |

2517 |

115 |

110 |

109.5 |

44 |

19 |

15 |

- |

- |

|

WHG30-2 |

3020 |

145 |

140 |

139.5 |

50 |

20 |

15 |

17 |

17 |

|

WHG35 |

3525 |

190 |

180 |

179.5 |

65 |

25 |

25 |

22 |

22 |

|

WHG40-1 |

4030 |

200 |

190 |

189.0 |

76 |

32 |

30 |

25 |

25 |

|

WHG40-2 |

4040 |

200 |

190 |

189.0 |

101 |

32 |

30 |

34 |

34 |

|

WHG45-1 |

4535 |

210 |

200 |

199.5 |

89 |

40 |

30 |

30 |

30 |

|

WHG45-2 |

4545 |

210 |

200 |

199.5 |

114 |

40 |

30 |

38 |

38 |

|

WHG50-1 |

5040 |

230 |

220 |

219.5 |

102 |

40 |

35 |

34 |

34 |

|

WHG50-2 |

5050 |

230 |

220 |

219.5 |

127 |

40 |

35 |

42 |

42 |

“GH”: natation represents welding relief

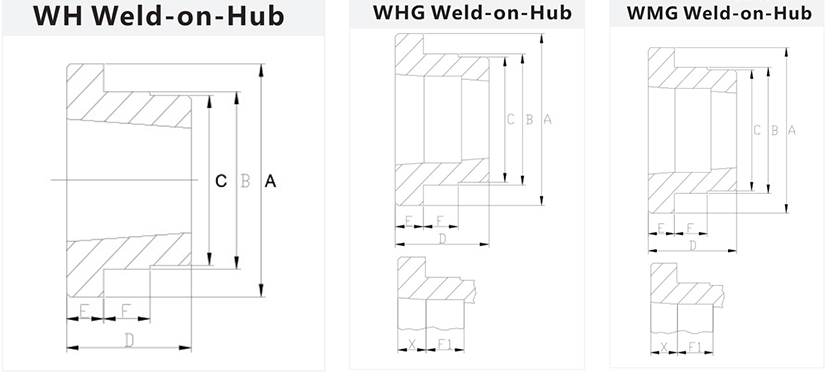

WMG Weld-on-Hub

|

Hub Reference |

Bush Size |

A |

B |

C |

D |

E |

F |

Fl |

X |

|

WMG12 |

1210 |

70 |

60 |

58 |

26 |

9 |

10 |

9 |

9 |

|

WMG16-1 |

1610 |

83 |

70 |

68 |

26 |

9 |

10 |

9 |

9 |

|

WMG16-1 |

1615 |

83 |

70 |

68 |

38 |

16 |

11 |

13 |

13 |

|

WMG20 |

2012 |

95 |

90 |

88 |

32 |

12 |

12 |

11 |

11 |

|

WMG25 |

2517 |

127 |

110 |

108 |

44 |

19 |

13 |

15 |

15 |

|

WMG30-2 |

3020 |

150 |

130 |

125 |

50 |

20 |

15 |

17 |

17 |

|

WMG30-3 |

3030 |

150 |

130 |

125 |

76 |

25 |

19 |

25 |

25 |

|

WMG35 |

3535 |

184 |

155 |

151 |

89 |

32 |

25 |

30 |

30 |

|

WMG40 |

4040 |

225 |

195 |

187 |

102 |

32 |

32 |

34 |

34 |

|

WMG45 |

4545 |

254 |

220 |

213 |

114 |

38 |

38 |

38 |

38 |

|

WMG50 |

5050 |

276 |

242 |

228 |

127 |

38 |

38 |

42 |

42 |

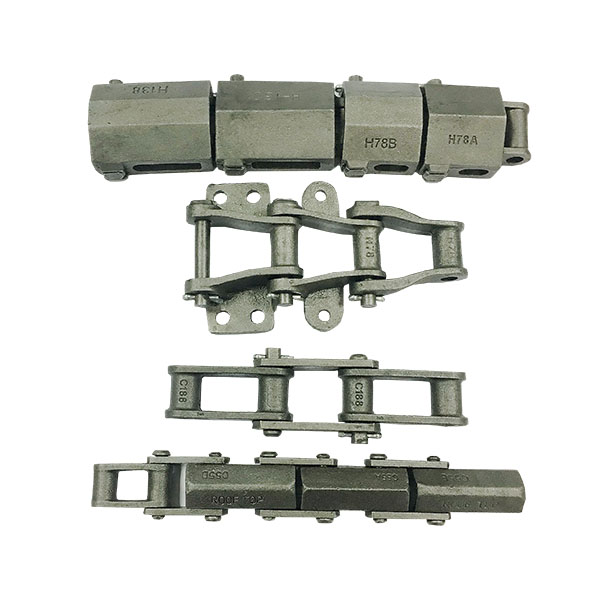

Weld-on-hubs are made of C20 steel and drilled, tapped and coned to accommodate tapered lock bushings. They can be used for welding into pulleys, sprockets, couplings, fan rotors, belt wheels, etc. These components must be securely mounted on shafting. Four types of weld-on-hubs are available off the shelf.Type:W, WG, WH, WHG, WM, WMG taper bore hubs.

Product detail pictures:

Related Product Guide:

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Factory made hot-sale Sleeve Coupling - Weld-On-Hubs, Type W, WH,WM per C20 Material – GOODLUCK , The product will supply to all over the world, such as: Puerto Rico, Las Vegas, Cambodia, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.