Factory making Sprockets - Cast Iron Sprockets per European Standard – GOODLUCK

Factory making Sprockets - Cast Iron Sprockets per European Standard – GOODLUCK Detail:

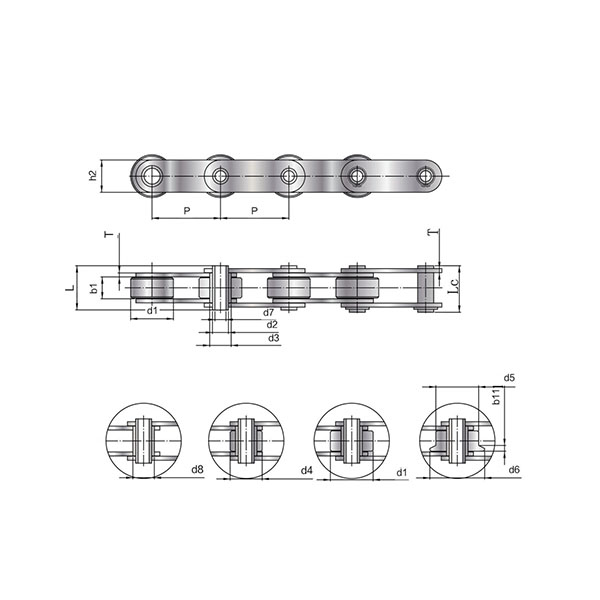

Stock Bore For Chain Acc. to DIN 8187-ISO/R 606 Material:GG22 GG25

06B-1-2-3 SPROCKETS 3/8″ x 7/32″ For Chain Acc. to DIN 8187

|

z |

de |

dp |

SIMPLEX |

DUPLEX |

TRIPLEX |

||||||

|

dm |

D1 |

A |

dm |

D2 |

A |

dm |

D3 |

A |

|||

|

38 |

119.5 |

115.35 |

70 |

20 |

32 |

80 |

20 |

40 |

90 |

24 |

56 |

|

45 |

140.7 |

136.55 |

70 |

20 |

32 |

80 |

20 |

40 |

90 |

24 |

56 |

|

57 |

176.9 |

172.91 |

70 |

20 |

32 |

80 |

20 |

40 |

90 |

24 |

56 |

|

76 |

234.9 |

230.49 |

70 |

20 |

32 |

80 |

20 |

40 |

100 |

24 |

56 |

|

95 |

292.5 |

288.08 |

80 |

20 |

40 |

90 |

20 |

45 |

100 |

24 |

56 |

|

114 |

349.6 |

345.68 |

80 |

20 |

40 |

95 |

20 |

45 |

100 |

24 |

56 |

|

150 |

459.2 |

454.82 |

90 |

24 |

45 |

100 |

24 |

50 |

125 |

24 |

60 |

08B-1-2-3 SPROCKETS 1/2 “x 5/16″

|

z |

de |

dp

|

SIMPLEX |

DUPLEX |

TRIPLEX |

||||||

|

dm |

D1 |

A |

dm |

D2 |

A |

dm |

D3 |

A |

|||

|

38 |

158.6 |

153.80 |

70 |

20 |

40 |

90 |

24 |

50 |

100 |

24 |

60 |

|

45 |

188.0 |

182.07 |

70 |

20 |

40 |

90 |

24 |

50 |

100 |

24 |

60 |

|

57 |

236.4 |

230.54 |

70 |

20 |

40 |

90 |

24 |

50 |

100 |

24 |

60 |

|

76 |

313.3 |

307.33 |

80 |

24 |

40 |

100 |

24 |

56 |

100 |

24 |

60 |

|

95 |

390.1 |

384.11 |

80 |

24 |

45 |

100 |

24 |

56 |

120 |

24 |

67 |

|

114 |

466.9 |

460.90 |

80 |

24 |

45 |

100 |

24 |

63 |

120 |

24 |

67 |

10B-1-2-3 SPROCKETS 5/8″ x 3/8″

|

z |

de |

dp |

SIMPLEX |

DUPLEX |

TRIPLEX |

||||||

|

dm |

D1 |

A |

dm |

D2 |

A |

dm |

D3 |

A |

|||

|

38 |

199.2 |

192.24 |

80 |

20 |

40 |

100 |

30 |

50 |

100 |

32 |

60 |

|

45 |

235.0 |

227.58 |

80 |

20 |

40 |

100 |

30 |

50 |

100 |

32 |

60 |

|

57 |

296.0 |

288.18 |

90 |

24 |

45 |

100 |

30 |

56 |

100 |

32 |

63 |

|

76 |

392.1 |

384.16 |

90 |

24 |

50 |

100 |

30 |

63 |

110 |

35 |

67 |

|

95 |

488.5 |

480.14 |

100 |

24 |

56 |

110 |

30 |

63 |

125 |

35 |

70 |

|

114 |

584.1 |

576.13 |

100 |

24 |

56 |

125 |

30 |

70 |

125 |

35 |

80 |

12B-1-2-3 SPROCKETS 3/4″ x 7/16″

|

z |

de |

dp |

SIMPLEX |

DUPLEX |

TRIPLEX |

||||||

|

dm |

D1 |

A |

dm |

D2 |

A |

dm |

D3 |

A |

|||

|

38 |

239.0 |

230.69 |

100 |

24 |

56 |

110 |

30 |

63 |

140 |

30 |

70 |

|

45 |

282.5 |

273.10 |

100 |

24 |

56 |

110 |

30 |

63 |

140 |

30 |

70 |

|

57 |

354.0 |

345.81 |

100 |

30 |

56 |

120 |

30 |

63 |

140 |

40 |

70 |

|

76 |

469.9 |

460.99 |

100 |

30 |

56 |

135 |

30 |

63 |

160 |

40 |

75 |

|

95 |

585.1 |

576.17 |

100 |

30 |

65 |

135 |

30 |

70 |

170 |

40 |

82 |

|

114 |

700.6 |

691.36 |

100 |

30 |

65 |

135 |

30 |

70 |

170 |

50 |

82 |

16B-1-2-3 SPROCKETS 1″ x 17.02mm

|

z |

de |

dp |

SIMPLEX |

DUPLEX |

TRIPLEX |

||||||

|

dm |

D1 |

A |

dm |

D2 |

A |

dm |

D3 |

A |

|||

|

30 |

254.0 |

243.00 |

110 |

30 |

65 |

125 |

40 |

75 |

145 |

40 |

90 |

|

38 |

320.0 |

307.59 |

110 |

30 |

65 |

140 |

40 |

75 |

160 |

45 |

100 |

|

45 |

377.0 |

364.13 |

125 |

30 |

70 |

150 |

40 |

75 |

160 |

45 |

100 |

|

57 |

474.0 |

461.08 |

125 |

35 |

70 |

170 |

40 |

90 |

165 |

45 |

100 |

|

76 |

627.0 |

614.65 |

140 |

35 |

80 |

175 |

40 |

95 |

200 |

45 |

110 |

|

95 |

781.0 |

768.22 |

140 |

40 |

80 |

175 |

45 |

95 |

200 |

50 |

110 |

|

114 |

933.0 |

921.81 |

140 |

40 |

80 |

175 |

45 |

95 |

200 |

50 |

115 |

20B-1-2-3 SPROCKETS 1 “1/4 x 3/4″

|

z |

de |

dp |

SIMPLEX |

DUPLEX |

TRIPLEX |

||||||

|

dm |

D1 |

A |

dm |

II D2 |

A |

dm |

D3 |

A |

|||

|

30 |

318.9 |

303.75 |

115 |

35 |

70 |

130 |

40 |

80 |

160 |

50 |

100 |

|

38 |

399.6 |

384.49 |

125 |

35 |

70 |

140 |

45 |

90 |

180 |

56 |

110 |

|

45 |

470.3 |

455.17 |

125 |

35 |

70 |

140 |

45 |

90 |

180 |

56 |

110 |

|

57 |

591.5 |

576.36 |

135 |

40 |

80 |

160 |

50 |

100 |

180 |

60 |

125 |

|

76 |

783.5 |

768.32 |

140 |

40 |

90 |

180 |

50 |

100 |

200 |

60 |

140 |

24B-1-2-3 SPROCKETS 1 “1/2 x 1″

|

z |

de |

dp |

SIMPLEX |

DUPLEX |

TRIPLEX |

||||||

|

dm |

D1 |

A |

dm |

D2 |

A |

dm |

D3 |

A |

|||

|

30 |

379.5 |

364.50 |

130 |

40 |

85 |

160 |

40 |

95 |

180 |

60 |

150 |

|

38 |

476.2 |

461.39 |

140 |

45 |

90 |

180 |

45 |

100 |

200 |

60 |

150 |

|

45 |

561.2 |

546.20 |

140 |

45 |

90 |

180 |

45 |

100 |

200 |

60 |

150 |

|

57 |

706.5 |

691.63 |

160 |

45 |

100 |

200 |

55 |

110 |

200 |

70 |

150 |

|

76 |

936.9 |

921.98 |

170 |

45 |

100 |

220 |

55 |

120 |

250 |

70 |

150 |

These plate wheels and sprocket wheels are applied when larger teeth are necessary. This is, among other things, to save weight and material, which makes it also interesting to choose these wheels because it saves money. These wheels can also be fitted with taperbush connections.Long lifespan

Simplex, duplex and triplex

Lots of shapes and sizes

According to drawing possible

DIN 8187 – ISO / R 606

Material: Cast Iron EN-GJL-200 UNI EN 1561

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Factory making Sprockets - Cast Iron Sprockets per European Standard – GOODLUCK , The product will supply to all over the world, such as: Rwanda, Chile, Gambia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.