Factory making Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK

Factory making Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK Detail:

| NK15B | |

| SPROCKETS | mm |

| Tooth width (T) | 2.0 |

| CHAIN | mm |

| Pitch (P) | 4.7625 |

| Internal width | 2.38 |

| Roller Φ (Dr) | 2.48 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK15B |

11 |

19.0 |

16.90 |

4 |

5 |

7 |

11 |

10 |

9 |

C45 Solid |

|

12 |

20.5 |

18.40 |

4 |

5 |

8 |

12 |

10 |

10 |

||

|

13 |

22.0 |

19.90 |

4 |

5 |

9 |

14 |

10 |

14 |

||

|

14 |

23.5 |

21.40 |

6 |

7 |

10 |

15 |

12 |

17 |

||

|

15 |

25.0 |

22.91 |

6 |

7 |

12 |

17 |

12 |

22 |

||

|

16 |

26.5 |

24.41 |

8 |

9 |

12 |

18 |

1Z |

23 |

||

|

17 |

28.0 |

25.92 |

8 |

9 |

14 |

20 |

14 |

32 |

||

|

18 |

295 |

27.43 |

8 |

9 |

14 |

22 |

14 |

40 |

||

|

19 |

3L0 |

28.93 |

8 |

9 |

15 |

23 |

14 |

44 |

||

|

20 |

32.5 |

30.44 |

8 |

9 |

15 |

24 |

14 |

49 |

||

|

21 |

34.0 |

31.95 |

8 |

9 |

17 |

26 |

14 |

57 |

||

|

22 |

355 |

33.46 |

8 |

9 |

17 |

27 |

14 |

62 |

||

|

23 |

37.5 |

34.98 |

8 |

9 |

17 |

28 |

14 |

68 |

||

|

24 |

39-0 |

36.49 |

8 |

9 |

20 |

30 |

16 |

88 |

||

|

25 |

405 |

38.00 |

8 |

9 |

20 |

32 |

16 |

100 |

||

|

26 |

42.0 |

39.51 |

10 |

11 |

22 |

33 |

16 |

104 |

||

|

27 |

43.5 |

41.02 |

10 |

11 |

25 |

35 |

16 |

117 |

||

|

28 |

45,0 |

42.54 |

10 |

11 |

25 |

37 |

16 |

131 |

||

|

29 |

46,5 |

44.05 |

10 |

11 |

25 |

38 |

16 |

139 |

||

|

30 |

48.0 |

45.56 |

10 |

11 |

25 |

39 |

16 |

147 |

||

|

31 |

49,5 |

47.08 |

10 |

11 |

25 |

40 |

18 |

175 |

||

|

32 |

SL0 |

48.59 |

10 |

11 |

25 |

40 |

18 |

176 |

||

|

33 |

52.5 |

50.10 |

10 |

11 |

25 |

40 |

18 |

178 |

||

|

34 |

54.0 |

51.62 |

10 |

11 |

25 |

40 |

18 |

180 |

||

|

35 |

55.5 |

53.13 |

10 |

11 |

25 |

40 |

18 |

182 |

||

NK25B

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.3 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

g |

|||||||

| NK25B |

10 |

23 |

2055 |

6.5 |

8.5 |

8.5 |

14 |

IS |

30 |

C45 Solid |

|

11 |

25 |

22.54 |

6.5 |

8.5 |

8.5 |

15 |

15 |

30 |

||

|

12 |

28 |

24.53 |

7.5 |

9.5 |

9.5 |

15 |

15 |

30 |

||

|

13 |

30 |

2653 |

7.5 |

9.5 |

10 |

18 |

15 |

50 |

||

|

14 |

32 |

2854 |

7.5 |

9.5 |

10 |

20 |

IS |

50 |

||

|

15 |

34 |

3054 |

75 |

9.5 |

10 |

20 |

IS |

50 |

||

|

16 |

36 |

3255 |

95 |

11.5 |

12 |

25 |

15 |

60 |

||

|

17 |

38 |

34S6 |

9.5 |

11.5 |

12 |

25 |

IS |

70 |

||

|

18 |

40 |

3657 |

9.5 |

115 |

12 |

25 |

15 |

70 |

||

|

19 |

42 |

3858 |

9.5 |

11.5 |

16 |

28 |

15 |

80 |

||

|

20 |

44 |

40.59 |

9.5 |

11.5 |

16 |

28 |

15 |

80 |

||

|

21 |

46 |

42.61 |

95 |

11.5 |

16 |

28 |

15 |

90 |

||

|

22 |

48 |

44.65 |

9.5 |

11.5 |

16 |

30 |

IS |

100 |

||

|

23 |

50 |

46.63 |

9.5 |

11.5 |

16 |

30 |

IS |

110 |

||

|

24 |

52 |

48.6S |

9.5 |

11.5 |

16 |

30 |

IS |

120 |

||

|

25 |

54 |

50.66 |

9S |

11.5 |

20 |

35 |

IS |

140 |

||

|

26 |

56 |

52.68 |

95 |

11.5 |

20 |

35 |

IS |

140 |

||

|

27 |

58 |

54.70 |

95 |

11.5 |

20 |

35 |

15 |

150 |

||

|

28 |

60 |

56.71 |

9.5 |

11.5 |

20 |

35 |

IS |

150 |

||

|

29 |

62 |

5873 |

9,5 |

11.5 |

20 |

35 |

15 |

160 |

||

|

30 |

64 |

60.75 |

9S |

11.5 |

20 |

35 |

15 |

160 |

||

|

31 |

66 |

62.77 |

10.5 |

12.5 |

22 |

40 |

20 |

200 |

||

|

32 |

68 |

64.78 |

10.5 |

12.5 |

22 |

40 |

20 |

200 |

||

|

33 |

70 |

66.80 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

34 |

72 |

68.82 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

35 |

74 |

70^4 |

10.5 |

12.5 |

22 |

40 |

20 |

210 |

||

|

36 |

76 |

72.86 |

10.5 |

12.5 |

22 |

40 |

20 |

220 |

||

|

37 |

78 |

74.88 |

10,5 |

12.5 |

22 |

3 |

20 |

260 |

||

|

38 |

80 |

76.90 |

10.5 |

12.5 |

22 |

40 |

20 |

260 |

||

|

39 |

82 |

78.91 |

10.5 |

12.5 |

22 |

40 |

20 |

270 |

||

|

40 |

84 |

80.93 |

10.5 |

12.5 |

22 |

40 |

20 |

270 |

||

|

41 |

87 |

82.95 |

10.5 |

12.5 |

30 |

50 |

20 |

320 |

||

|

42 |

89 |

84.97 |

10.5 |

12.5 |

30 |

SO |

20 |

320 |

||

|

43 |

91 |

86.99 |

10.5 |

12.5 |

30 |

50 |

20 |

400 |

||

|

44 |

93 |

89.01 |

10.5 |

12.5 |

30 |

50 |

20 |

410 |

||

|

45 |

95 |

91.03 |

10.5 |

12.5 |

30 |

50 |

20 |

410 |

||

|

4S |

101 |

97.09 |

10.5 |

12.5 |

30 |

50 |

20 |

430 |

||

|

50 |

105 |

10113 |

10.5 |

12.5 |

30 |

50 |

20 |

460 |

||

|

54 |

113 |

10921 |

10.5 |

12.5 |

30 |

50 |

20 |

470 |

||

|

60 |

125 |

12133 |

10.5 |

12.5 |

30 |

50 |

20 |

510 |

||

|

65 |

135 |

13L43 |

11.5 |

13.5 |

30 |

50 |

20 |

720 |

||

|

70 |

145 |

14154 |

11.5 |

13.5 |

30 |

50 |

20 |

770 |

||

|

75 |

1S5 |

151.64 |

11.5 |

13.5 |

30 |

50 |

20 |

820 |

||

|

80 |

165 |

161.74 |

11.5 |

13.5 |

30 |

50 |

20 |

880 |

NK35B

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.525 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK35B |

9 |

32 |

27.85 |

85 |

10.5 |

11 |

★21.5 |

20 |

0.06 |

C45 Solid |

|

10 |

34 |

30.82 |

85 |

105 |

12 |

★24.5 |

20 |

0.08 |

||

|

11 |

38 |

33.81 |

95 |

115 |

14 |

★27 |

20 |

0.09 |

||

|

12 |

41 |

36,81 |

9S |

11.5 |

16 |

★50.5 |

20 |

042 |

||

|

13 |

44 |

39.80 |

95 |

11.5 |

18 |

★32 |

20 |

0.12 |

||

|

14 |

47 |

42.81 |

9_5 |

11.5 |

18 |

32 |

20 |

0.12 |

||

|

15 |

51 |

45.81 |

95 |

11.5 |

20 |

35 |

20 |

0.16 |

||

|

16 |

54 |

48.82 |

95 |

11.5 |

20 |

37 |

20 |

0.19 |

||

|

17 |

57 |

51.84 |

115 |

13S |

25 |

41 |

20 |

022 |

||

|

18 |

60 |

54,85 |

115 |

13.5 |

25 |

44 |

20 |

0.25 |

||

|

19 |

63 |

57.87 |

115 |

135 |

28 |

47 |

20 |

0.28 |

||

|

20 |

66 |

60.89 |

115 |

13.5 |

30 |

50 |

20 |

0.32 |

||

|

21 |

69 |

63.91 |

115 |

135 |

32 |

53 |

20 |

036 |

||

|

22 |

72 |

6&93 |

115 |

13.5 |

35 |

56 |

20 |

0.37 |

||

|

23 |

75 |

69.95 |

115 |

135 |

38 |

60 |

20 |

0.38 |

||

|

24 |

78 |

72.97 |

115 |

13.5 |

32 |

53 |

22 |

0.43 |

||

|

25 |

81 |

76.00 |

115 |

13.5 |

32 |

53 |

22 |

0.44 |

||

|

26 |

84 |

79.02 |

115 |

133 |

32 |

53 |

22 |

0.45 |

||

|

27 |

87 |

82.05 |

115 |

135 |

32 |

53 |

22 |

0.46 |

||

|

28 |

90 |

8S.07 |

113 |

13.5 |

32 |

53 |

22 |

0.48 |

||

|

29 |

93 |

8810 |

115 |

13S |

32 |

53 |

22 |

0.49 |

||

|

30 |

96 |

91.12 |

115 |

13.5 |

32 |

53 |

22 |

051 |

||

|

31 |

99 |

94.15 |

115 |

135 |

32 |

S3 |

22 |

053 |

||

|

32 |

102 |

97.18 |

115 |

13.5 |

32 |

53 |

22 |

0.54 |

||

|

33 |

105 |

100.20 |

115 |

135 |

32 |

53 |

22 |

056 |

||

|

34 |

109 |

103.23 |

115 |

135 |

32 |

53 |

22 |

0.57 |

||

|

35 |

112 |

106.26 |

115 |

13.5 |

32 |

S3 |

22 |

0.59 |

||

|

36 |

115 |

109.29 |

125 |

145 |

32 |

53 |

22 |

0.61 |

||

|

37 |

118 |

112.31 |

125 |

14.5 |

42 |

63 |

25 |

0.80 |

||

|

38 |

121 |

115.34 |

125 |

145 |

42 |

63 |

25 |

0.82 |

||

|

39 |

124 |

118.37 |

125 |

145 |

42 |

63 |

25 |

0.84 |

||

|

40 |

127 |

121.40 |

125 |

143 |

42 |

63 |

25 |

0.85 |

||

|

41 |

130 |

124.43 |

16 |

18 |

42 |

63 |

25 |

0.91 |

Fe360 Welding

|

|

|

42 |

133 |

127.46 |

16 |

18 |

42 |

63 |

25 |

0.93 |

||

|

43 |

136 |

130.49 |

16 |

18 |

42 |

63 |

25 |

0.95 |

||

|

44 |

139 |

133.52 |

16 |

18 |

42 |

63 |

25 |

0.97 |

||

|

45 |

142 |

136.55 |

16 |

18 |

42 |

63 |

25 |

1.00 |

||

|

46 |

145 |

139.58 |

16 |

18 |

42 |

63 |

25 |

1.01 |

||

|

47 |

148 |

142.61 |

16 |

18 |

42 |

63 |

25 |

1.03 |

||

|

48 |

151 |

145.64 |

16 |

18 |

42 |

63 |

25 |

1.05 |

||

|

SO |

157 |

151.70 |

16 |

18 |

42 |

63 |

25 |

1.07 |

||

|

53 |

166 |

160.78 |

16 |

18 |

42 |

63 |

25 |

1.09 |

||

|

54 |

169 |

163.81 |

16 |

18 |

42 |

63 |

25 |

1.10 |

||

|

55 |

172 |

166.85 |

16 |

18 |

42 |

63 |

25 |

1.25 |

||

|

60 |

187 |

182.00 |

16 |

18 |

42 |

63 |

25 |

1.30 |

||

|

64 |

200 |

194.12 |

16 |

18 |

42 |

63 |

25 |

1,46 |

||

|

65 |

203 |

197.15 |

16 |

18 |

45 |

68 |

25 |

1.67 |

||

|

70 |

218 |

212.30 |

16 |

18 |

45 |

68 |

25 |

1.80 |

||

|

75 |

233 |

227.46 |

16 |

18 |

45 |

68 |

25 |

1.90 |

||

|

80 |

248 |

242.61 |

16 |

18 |

45 |

68 |

25 |

2.40 |

| Teeth | s | GD |

| 9 | 4.4 | 17 |

| 10 | 20 | |

| 11 | 23 | |

| 12 | 26 | |

| 13 | 29 |

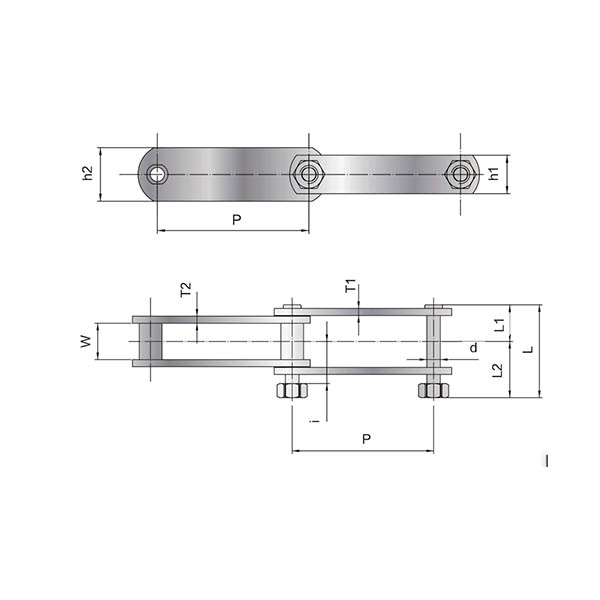

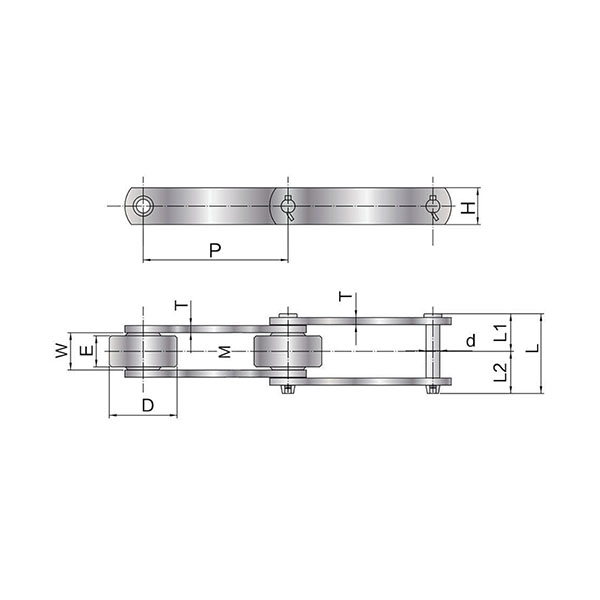

GL offers sprockets with an emphasis on precision engineering and perfect quality. Our stock Pilot Bore hole (PB) plate wheel and sprockets are ideal for being machined to the bore which customers desire need as different shaft diamater.

We offer Type A (hub-less) plate wheels from #25 (0.250 “), #35 (0.375 “) , #40 (0.500 “) till #240(3″) pitches in stock. The finished plate wheels are some in stock.

We also offer Type B(hub) sprockets from #25 (0.250 “), #35 (0.375 “), #40 (0.500 “), #41 (0.500 “), #50 (0.625 “) , #50 (0.625 “) till #240(3″) pitch in stock. The finished sprockets are some in stock.

Teeth of PB plate wheel and sprockets hardened are avilable.

Material are made of steel C45.

We also offer PB plate wheels and sprockets in stainless steel SS304 for these sizes.

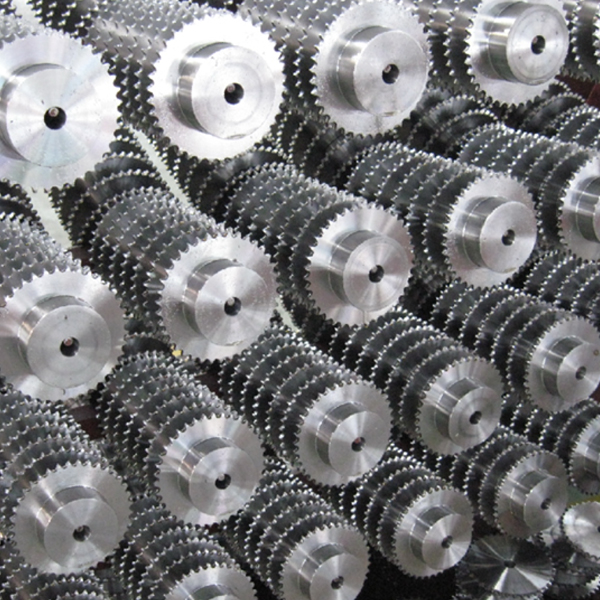

Product detail pictures:

Related Product Guide:

The organization keeps for the procedure concept "scientific administration, superior quality and effectiveness primacy, shopper supreme for Factory making Sprockets - Stock Bore Sprockets per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: Pakistan, Southampton, Madras, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.