Manufacturer for Coupling Pin - TGL (GF) Couplings,Curved Gear Couplings with Yellow Nylon Sleeve – GOODLUCK

Manufacturer for Coupling Pin - TGL (GF) Couplings,Curved Gear Couplings with Yellow Nylon Sleeve – GOODLUCK Detail:

Curved gear coupling

TGL Series (GF-SERIES)

Product features

• Double section curved surface coupling

• Widely used in various fields of machinery and hydraulics

• Non maintenance of nylon and steel material

• Compensation for axial, radial and angular errors

• The axial insert assembly is very convenient

• The product hole tolerance is H7 according Io the ISO standard, and the tolerance of keyway width is in accordance with the standard, DIN6885/1byJS9, Another inch and the cone hole

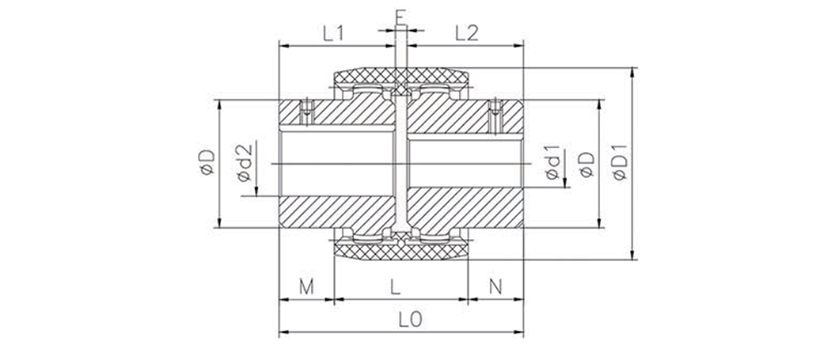

• For installation size, see the table below:

|

Model |

Finished bore dl , d2

|

Dimension(mm) |

Coupling Weightwith Max, Aperture |

RatedTorque |

|||||||||||

|

General |

Lengthened |

Premachlned Bore |

Max , aperture |

L1,L2 |

L0 |

L |

M,N |

E |

L1,L2 Max |

D1 |

D |

Weight of Nylon-seelve |

Total Weight |

N.m |

|

|

TGL-14 |

TGL-14-L |

- |

Customers could order finished |

14 |

23 |

50 |

37 |

6.5 |

4 |

40 |

40 |

24 |

0.02 |

0.14 |

10 |

|

TGL-19 |

TGL-19-L |

- |

19 |

25 |

54 |

37 |

8.5 |

4 |

40 |

48 |

30 |

0.03 |

0.21 |

16 |

|

|

TGL-24 |

TGL-24-L |

- |

24 |

26 |

56 |

41 |

7.5 |

4 |

50 |

52 |

36 |

0.04 |

0.25 |

20 |

|

|

TGL-28 |

TGL-28-L |

- |

28 |

40 |

84 |

46 |

19 |

4 |

55 |

66 |

44 |

0.07 |

0.62 |

45 |

|

|

TGL-32 |

TGL-32-L |

- |

32 |

40 |

84 |

48 |

18 |

4 |

55 |

76 |

50 |

0.09 |

0.83 |

60 |

|

|

TGL-38 |

TGL-38-L |

- |

38 |

40 |

84 |

48 |

18 |

4 |

60 |

83 |

58 |

0J1 |

1.04 |

80 |

|

|

TGL-42 |

TGL-42-L |

- |

42 |

42 |

88 |

50 |

19 |

4 |

60 |

92 |

65 |

0.14 |

1.41 |

100 |

|

|

TGL-48 |

TGL-48-L |

- |

48 |

50 |

104 |

50 |

27 |

4 |

60 |

92 |

67 |

0.16 |

1.43 |

140 |

|

|

TGL-55 |

TGL-55-L |

- |

55 |

52 |

108 |

58 |

25 |

4 |

65 |

114 |

82 |

0.26 |

2.50 |

240 |

|

|

TGL-65 |

TGL-65-L |

- |

65 |

55 |

114 |

68 |

23 |

4 |

70 |

132 |

95 |

0.39 |

3.58 |

380 |

|

The GF Coupling consists of two steel hubs with

external crowned and barrelled gear teeth, Oxidation blacked protection, connected by a synthetic resin sleeve. The

sleeve is manufactured from high molecular weight polyamide,

thermally conditioned and impregnated with solid lubricant to

provide a long maintenance-free life. This sleeve has high resistance

to atmospheric humidity and an operating temperature range of

–20˚C to +80˚C with ability to withstand 120˚C for short durations.

The GF Series Couplings are made with two hub lengths; a standard hub suitable for most applications, and a longer hub.

Product detail pictures:

Related Product Guide:

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for Manufacturer for Coupling Pin - TGL (GF) Couplings,Curved Gear Couplings with Yellow Nylon Sleeve – GOODLUCK , The product will supply to all over the world, such as: Colombia, Italy, Venezuela, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

){%XYQC.png)