Manufacturer for Steel Sprockets - Platewheels per Asian Standard – GOODLUCK

Manufacturer for Steel Sprockets - Platewheels per Asian Standard – GOODLUCK Detail:

K25A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.30 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K25A |

10 |

23 |

20.55 |

9 |

11 |

0.02 |

C45 Solid |

|

12 |

28 |

24.53 |

9 |

11 |

0.03 |

||

|

13 |

30 |

26.53 |

9 |

11 |

0.04 |

||

|

14 |

32 |

28.54 |

9 |

11 |

0.04 |

||

|

15 |

34 |

30.54 |

9 |

11 |

0.05 |

||

|

16 |

36 |

32.55 |

9 |

11 |

0.05 |

||

|

17 |

38 |

34.56 |

9 |

11 |

0.07 |

||

|

18 |

40 |

36.57 |

9 |

11 |

0.07 |

||

|

20 |

44 |

40.59 |

9 |

11 |

0.09 |

||

|

24 |

52 |

48.65 |

9 |

11 |

0.14 |

||

|

25 |

54 |

50.66 |

9 |

11 |

0.16 |

||

|

27 |

58 |

54.70 |

9 |

11 |

0.17 |

||

|

28 |

60 |

56.71 |

9 |

11 |

018 |

||

|

29 |

62 |

58.73 |

9 |

11 |

0.20 |

||

|

30 |

64 |

60.75 |

10 |

12 |

0.23 |

||

|

32 |

68 |

64.78 |

10 |

12 |

0.27 |

||

|

33 |

70 |

66.80 |

10 |

12 |

0.28 |

||

|

35 |

74 |

70.84 |

10 |

12 |

0.30 |

||

|

36 |

76 |

72.86 |

10 |

12 |

032 |

||

|

37 |

78 |

74.88 |

10 |

12 |

0.37 |

||

|

38 |

80 |

76.90 |

10 |

12 |

0.41 |

||

|

40 |

84 |

80.93 |

11 |

13 |

0.43 |

||

|

42 |

89 |

84.97 |

11 |

13 |

0.47 |

||

|

45 |

95 |

91.03 |

11 |

13 |

0,50 |

||

|

50 |

105 |

101.13 |

11 |

13 |

0.59 |

||

|

55 |

115 |

111.23 |

11 |

13 |

0.70 |

||

|

60 |

125 |

121.33 |

11 |

13 |

0.87 |

||

|

70 |

145 |

141.54 |

11 |

13 |

1.81 |

||

|

75 |

155 |

151.64 |

12 |

14 |

1.37 |

||

|

80 |

165 |

161.74 |

12 |

14 |

1.62 |

||

K25A

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.25 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K35A |

10 |

34 |

30.82 |

9 |

11 |

0.02 |

C45 Solid |

|

11 |

38 |

33.81 |

9 |

11 |

0.03 |

||

|

12 |

41 |

36.80 |

9 |

11 |

0.03 |

||

|

13 |

44 |

39.80 |

9 |

11 |

0.04 |

||

|

14 |

47 |

42.81 |

9 |

11 |

0.04 |

||

|

15 |

51 |

45.81 |

9 |

11 |

0.05 |

||

|

16 |

54 |

48.82 |

9 |

11 |

0.05 |

||

|

17 |

57 |

51.84 |

11 |

13 |

0.07 |

||

|

18 |

60 |

54.85 |

11 |

13 |

0.07 |

||

|

19 |

63 |

57.87 |

11 |

13 |

0.09 |

||

|

20 |

66 |

60.89 |

11 |

13 |

0.09 |

||

|

21 |

69 |

63.91 |

11 |

13 |

0.11 |

||

|

22 |

72 |

66.93 |

11 |

13 |

0.11 |

||

|

23 |

75 |

69,95 |

11 |

13 |

0.11 |

||

|

24 |

78 |

72.97 |

11 |

13 |

0.14 |

||

|

25 |

81 |

76.00 |

11 |

13 |

0.16 |

||

|

26 |

84 |

79.02 |

11 |

13 |

0.16 |

||

|

27 |

87 |

82,05 |

11 |

13 |

0.17 |

||

|

28 |

90 |

85.07 |

11 |

13 |

0.18 |

||

|

30 |

96 |

9142 |

11 |

13 |

0.23 |

||

|

32 |

102 |

97.18 |

11 |

13 |

0.27 |

||

|

33 |

105 |

100.20 |

11 |

13 |

0.28 |

||

|

34 |

109 |

103.23 |

11 |

13 |

0.29 |

||

|

35 |

112 |

106.26 |

11 |

13 |

0.30 |

||

|

36 |

115 |

109.29 |

12 |

14 |

0.32 |

||

|

38 |

121 |

115.34 |

12 |

14 |

0.37 |

||

|

40 |

127 |

121.40 |

12 |

14 |

0.40 |

||

|

42 |

133 |

127.46 |

16 |

18 |

0.43 |

||

|

45 |

142 |

136.55 |

16 |

18 |

0.49 |

||

|

46 |

145 |

139.58 |

16 |

18 |

0.51 |

||

|

4S |

151 |

145.64 |

16 |

18 |

0.55 |

||

|

50 |

157 |

151.70 |

16 |

18 |

0.60 |

||

|

54 |

169 |

163.81 |

16 |

18 |

0.70 |

||

|

55 |

172 |

166.85 |

16 |

18 |

0.71 |

||

|

60 |

187 |

182.00 |

16 |

18 |

0.80 |

||

|

65 |

203 |

197.15 |

16 |

18 |

1.02 |

||

|

70 |

218 |

212,30 |

16 |

18 |

1.18 |

||

|

80 |

24B |

242.60 |

16 |

18 |

1.50 |

||

K410A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 12.70 |

| Internal width | 3.4 |

| Roller Φ (Dr) | 7.75 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

| K410A |

8 |

38 |

33.19 |

10 |

12 |

0.01 |

C45 Solid |

|

9 |

42 |

37.13 |

10 |

12 |

0.02 |

||

|

10 |

46 |

41.10 |

11 |

13 |

0.05 |

||

|

11 |

51 |

45.08 |

12 |

14 |

0.09 |

||

|

12 |

55 |

49.07 |

12 |

14 |

0.10 |

||

|

13 |

59 |

53.07 |

15 |

17 |

0,12 |

||

|

14 |

63 |

57.07 |

15 |

17 |

0.14 |

||

|

IS |

67 |

61.08 |

15 |

17 |

0.16 |

||

|

16 |

71 |

65.10 |

15 |

17 |

0.18 |

||

|

17 |

76 |

69.12 |

15 |

17 |

0.20 |

||

|

18 |

80 |

73.14 |

15 |

17 |

0.23 |

||

|

19 |

84 |

77.16 |

15 |

17 |

0.26 |

||

|

20 |

88 |

81.18 |

16 |

18 |

0.29 |

||

|

21 |

92 |

85.21 |

16 |

18 |

0.30 |

||

|

22 |

96 |

89.24 |

16 |

18 |

0.35 |

||

|

23 |

100 |

93.27 |

16 |

18 |

0.38 |

||

|

24 |

104 |

9730 |

16 |

18 |

0.40 |

||

|

25 |

108 |

101.33 |

16 |

18 |

0.45 |

||

|

26 |

112 |

105.36 |

16 |

18 |

0.49 |

||

|

27 |

116 |

109.40 |

16 |

18 |

0.50 |

||

|

28 |

120 |

113.43 |

16 |

18 |

0.56 |

||

|

29 |

124 |

117.46 |

16 |

18 |

0.60 |

||

|

30 |

128 |

12L50 |

16 |

18 |

0.63 |

||

|

31 |

133 |

125.53 |

16 |

18 |

0.65 |

||

|

32 |

137 |

129.57 |

16 |

18 |

0.70 |

||

|

33 |

141 |

133.61 |

16 |

18 |

0.75 |

||

|

34 |

145 |

137.64 |

16 |

18 |

0.80 |

||

|

35 |

149 |

141.68 |

16 |

18 |

0.85 |

||

|

36 |

153 |

145.72 |

18 |

20 |

0.90 |

||

|

37 |

157 |

149.75 |

18 |

20 |

0.99 |

||

|

38 |

161 |

153.79 |

18 |

20 |

1.00 |

||

|

39 |

165 |

157.83 |

18 |

20 |

1.18 |

||

|

40 |

169 |

161.87 |

18 |

20 |

1.20 |

||

|

41 |

173 |

165.91 |

18 |

20 |

1.20 |

||

|

42 |

177 |

169.94 |

18 |

20 |

1.25 |

||

|

44 |

185 |

178.02 |

18 |

20 |

135 |

||

|

45 |

189 |

182.06 |

18 |

20 |

1.40 |

||

|

46 |

193 |

186.10 |

18 |

20 |

1.49 |

||

|

47 |

197 |

190.14 |

18 |

20 |

1.58 |

||

|

48 |

201 |

194.18 |

18 |

20 |

1.63 |

||

|

49 |

205 |

198.22 |

18 |

20 |

1.73 |

||

|

50 |

209 |

202.26 |

18 |

20 |

1.80 |

||

|

52 |

218 |

210.34 |

18 |

20 |

1.93 |

||

|

54 |

226 |

Z18-42 |

18 |

20 |

2.00 |

||

|

60 |

250 |

242.66 |

18 |

20 |

2.60 |

||

K40A

| SPROCKETS | mm |

| Tooth width (T) | 7.2 |

| CHAIN | mm |

| Pitch (P) | 12.7 |

| Internal width | 7.95 |

| Roller Φ (Dr) | 7.95 |

|

Type |

Teeth |

Do |

Dp |

Bored Stock |

Min |

Wt kg |

Material |

|

K4OA |

10 |

46 |

41.10 |

9.5 |

115 |

0.05 |

C45 Solid |

|

11 |

51 |

45.08 |

10.5 |

12.5 |

0.09 |

||

|

12 |

55 |

49.07 |

11.5 |

13.5 |

0.10 |

||

|

13 |

59 |

53.07 |

13.5 |

15-5 |

0.12 |

||

|

14 |

63 |

57.07 |

13.5 |

15.5 |

0.14 |

||

|

15 |

67 |

61.08 |

13.5 |

15.5 |

0J6 |

||

|

16 |

71 |

65.10 |

13.5 |

15.5 |

0.18 |

||

|

17 |

76 |

69.12 |

13.5 |

15,5 |

0.20 |

||

|

18 |

80 |

73.14 |

13-5 |

15,5 |

0.23 |

||

|

19 |

84 |

77.16 |

13.5 |

15.5 |

0.26 |

||

|

20 |

88 |

81.18 |

14 |

16 |

0.29 |

||

|

21 |

92 |

85.21 |

14 |

16 |

0.30 |

||

|

22 |

96 |

89.24 |

14 |

16 |

0.35 |

||

|

23 |

100 |

93.27 |

14 |

16 |

0.38 |

||

|

24 |

104 |

97.30 |

14 |

16 |

0.40 |

||

|

25 |

108 |

101.33 |

14 |

16 |

0.45 |

||

|

26 |

112 |

105.36 |

14 |

16 |

0.49 |

||

|

27 |

116 |

109.40 |

14 |

16 |

0.50 |

||

|

28 |

120 |

113.43 |

14 |

16 |

0.56 |

||

|

29 |

124 |

117.46 |

14 |

16 |

0.60 |

||

|

30 |

128 |

121.50 |

14 |

16 |

0.63 |

||

|

31 |

133 |

125.53 |

14 |

16 |

0.65 |

||

|

32 |

137 |

129.57 |

14 |

16 |

0.70 |

||

|

33 |

141 |

133.61 |

14 |

16 |

0.75 |

||

|

34 |

145 |

137.64 |

14 |

16 |

0-80 |

||

|

35 |

149 |

141,68 |

14 |

16 |

0.85 |

||

|

36 |

153 |

145.72 |

16 |

18 |

0.90 |

||

|

37 |

157 |

149.75 |

16 |

18 |

0.99 |

||

|

38 |

161 |

153.79 |

16 |

18 |

1.00 |

||

|

39 |

165 |

157.83 |

16 |

18 |

1.15 |

||

|

40 |

169 |

161.87 |

16 |

18 |

1.20 |

||

|

41 |

173 |

165.91 |

16 |

18 |

1.20 |

||

|

42 |

177 |

169.95 |

16 |

18 |

1.25 |

||

|

43 |

181 |

173.98 |

16 |

18 |

1.30 |

||

|

44 |

185 |

178.02 |

16 |

18 |

1.35 |

||

|

45 |

189 |

182.06 |

16 |

18 |

1.40 |

||

|

46 |

193 |

186.10 |

16 |

18 |

1.49 |

||

|

47 |

197 |

190.14 |

16 |

18 |

1.58 |

||

| 48 |

201 |

194.18 |

16 |

18 |

1-63 |

||

|

49 |

205 |

198.22 |

16 |

18 |

1.73 |

||

|

50 |

209 |

202.26 |

16 |

18 |

1.80 |

||

|

51 |

214 |

206.30 |

16 |

18 |

1.88 |

||

|

52 |

218 |

210.34 |

16 |

18 |

1.93 |

||

|

53 |

222 |

214.38 |

16 |

18 |

1.98 |

||

|

54 |

226 |

218.42 |

16 |

18 |

2.00 |

||

|

S5 |

230 |

222.46 |

16 |

18 |

2.18 |

||

|

56 |

234 |

226.50 |

16 |

18 |

2.26 |

||

|

58 |

242 |

234.58 |

16 |

18 |

2.43 |

||

|

59 |

246 |

238.62 |

16 |

18 |

2.51 |

||

|

60 |

250 |

242,66 |

16 |

18 |

2.60 |

||

|

62 |

258 |

250.74 |

16 |

18 |

2.77 |

||

|

64 |

266 |

258.83 |

16 |

18 |

2.90 |

||

|

65 |

270 |

262.87 |

16 |

18 |

3.00 |

||

|

68 |

282 |

274.99 |

16 |

18 |

3.35 |

||

|

70 |

290 |

283.07 |

16 |

18 |

3.50 |

||

|

72 |

299 |

291.16 |

20 |

22 |

370 |

||

|

75 |

311 |

303,28 |

20 |

22 |

4.00 |

||

|

80 |

331 |

323.49 |

20 |

22 |

4.60 |

||

|

85 |

351 |

343.69 |

20 |

22 |

5.20 |

||

|

90 |

371 |

363.90 |

20 |

22 |

5.80 |

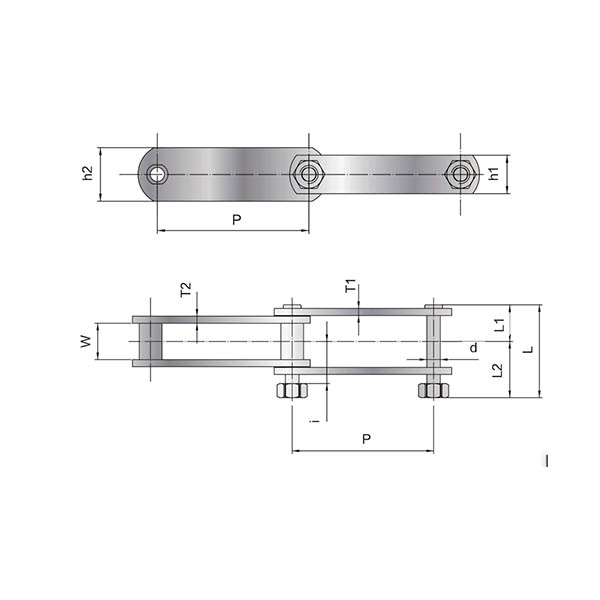

Plate wheel:

The plate wheel helps to determine the performance and service life of the chain

Plate wheels help determine the performance and service life of the chain, so GL provides appropriate corresponding plate wheels from its extensive inventory of all chains. This ensures proper alignment between the chain and the plate wheels and prevents fit differences that can affect the overall life of the chain drive. GL also manufactures the sprockets and plate wheels from solid materials or welded material exactly as the customer requires. GL offers a variety of tooth shapes and material options with or without hardened teeth. Designs include simplex, duplex, triplex and cast iron. European standard / AMERICA standard / Asian standard are avilable.

Product detail pictures:

Related Product Guide:

Being supported by an innovative and experienced IT team, we could present technical support on pre-sales & after-sales service for Manufacturer for Steel Sprockets - Platewheels per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: Borussia Dortmund, Romania, Iran, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.