OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK

OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK Detail:

K25A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 6.35 |

| Internal width | 3.18 |

| Roller Φ (Dr) | 3.30 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K25A |

10 |

23 |

20.55 |

9 |

11 |

0.02 |

C45 Solid |

|

12 |

28 |

24.53 |

9 |

11 |

0.03 |

||

|

13 |

30 |

26.53 |

9 |

11 |

0.04 |

||

|

14 |

32 |

28.54 |

9 |

11 |

0.04 |

||

|

15 |

34 |

30.54 |

9 |

11 |

0.05 |

||

|

16 |

36 |

32.55 |

9 |

11 |

0.05 |

||

|

17 |

38 |

34.56 |

9 |

11 |

0.07 |

||

|

18 |

40 |

36.57 |

9 |

11 |

0.07 |

||

|

20 |

44 |

40.59 |

9 |

11 |

0.09 |

||

|

24 |

52 |

48.65 |

9 |

11 |

0.14 |

||

|

25 |

54 |

50.66 |

9 |

11 |

0.16 |

||

|

27 |

58 |

54.70 |

9 |

11 |

0.17 |

||

|

28 |

60 |

56.71 |

9 |

11 |

018 |

||

|

29 |

62 |

58.73 |

9 |

11 |

0.20 |

||

|

30 |

64 |

60.75 |

10 |

12 |

0.23 |

||

|

32 |

68 |

64.78 |

10 |

12 |

0.27 |

||

|

33 |

70 |

66.80 |

10 |

12 |

0.28 |

||

|

35 |

74 |

70.84 |

10 |

12 |

0.30 |

||

|

36 |

76 |

72.86 |

10 |

12 |

032 |

||

|

37 |

78 |

74.88 |

10 |

12 |

0.37 |

||

|

38 |

80 |

76.90 |

10 |

12 |

0.41 |

||

|

40 |

84 |

80.93 |

11 |

13 |

0.43 |

||

|

42 |

89 |

84.97 |

11 |

13 |

0.47 |

||

|

45 |

95 |

91.03 |

11 |

13 |

0,50 |

||

|

50 |

105 |

101.13 |

11 |

13 |

0.59 |

||

|

55 |

115 |

111.23 |

11 |

13 |

0.70 |

||

|

60 |

125 |

121.33 |

11 |

13 |

0.87 |

||

|

70 |

145 |

141.54 |

11 |

13 |

1.81 |

||

|

75 |

155 |

151.64 |

12 |

14 |

1.37 |

||

|

80 |

165 |

161.74 |

12 |

14 |

1.62 |

||

K25A

| SPROCKETS | mm |

| Tooth width (T) | 4.3 |

| CHAIN | mm |

| Pitch (P) | 9.25 |

| Internal width | 4.78 |

| Roller Φ (Dr) | 5.08 |

|

Type |

Teeth |

Do |

Dp |

Bored |

wt kg |

Material |

|

|

Stock |

Min |

||||||

|

K35A |

10 |

34 |

30.82 |

9 |

11 |

0.02 |

C45 Solid |

|

11 |

38 |

33.81 |

9 |

11 |

0.03 |

||

|

12 |

41 |

36.80 |

9 |

11 |

0.03 |

||

|

13 |

44 |

39.80 |

9 |

11 |

0.04 |

||

|

14 |

47 |

42.81 |

9 |

11 |

0.04 |

||

|

15 |

51 |

45.81 |

9 |

11 |

0.05 |

||

|

16 |

54 |

48.82 |

9 |

11 |

0.05 |

||

|

17 |

57 |

51.84 |

11 |

13 |

0.07 |

||

|

18 |

60 |

54.85 |

11 |

13 |

0.07 |

||

|

19 |

63 |

57.87 |

11 |

13 |

0.09 |

||

|

20 |

66 |

60.89 |

11 |

13 |

0.09 |

||

|

21 |

69 |

63.91 |

11 |

13 |

0.11 |

||

|

22 |

72 |

66.93 |

11 |

13 |

0.11 |

||

|

23 |

75 |

69,95 |

11 |

13 |

0.11 |

||

|

24 |

78 |

72.97 |

11 |

13 |

0.14 |

||

|

25 |

81 |

76.00 |

11 |

13 |

0.16 |

||

|

26 |

84 |

79.02 |

11 |

13 |

0.16 |

||

|

27 |

87 |

82,05 |

11 |

13 |

0.17 |

||

|

28 |

90 |

85.07 |

11 |

13 |

0.18 |

||

|

30 |

96 |

9142 |

11 |

13 |

0.23 |

||

|

32 |

102 |

97.18 |

11 |

13 |

0.27 |

||

|

33 |

105 |

100.20 |

11 |

13 |

0.28 |

||

|

34 |

109 |

103.23 |

11 |

13 |

0.29 |

||

|

35 |

112 |

106.26 |

11 |

13 |

0.30 |

||

|

36 |

115 |

109.29 |

12 |

14 |

0.32 |

||

|

38 |

121 |

115.34 |

12 |

14 |

0.37 |

||

|

40 |

127 |

121.40 |

12 |

14 |

0.40 |

||

|

42 |

133 |

127.46 |

16 |

18 |

0.43 |

||

|

45 |

142 |

136.55 |

16 |

18 |

0.49 |

||

|

46 |

145 |

139.58 |

16 |

18 |

0.51 |

||

|

4S |

151 |

145.64 |

16 |

18 |

0.55 |

||

|

50 |

157 |

151.70 |

16 |

18 |

0.60 |

||

|

54 |

169 |

163.81 |

16 |

18 |

0.70 |

||

|

55 |

172 |

166.85 |

16 |

18 |

0.71 |

||

|

60 |

187 |

182.00 |

16 |

18 |

0.80 |

||

|

65 |

203 |

197.15 |

16 |

18 |

1.02 |

||

|

70 |

218 |

212,30 |

16 |

18 |

1.18 |

||

|

80 |

24B |

242.60 |

16 |

18 |

1.50 |

||

K410A

| SPROCKETS | mm |

| Tooth width (T) | 2.8 |

| CHAIN | mm |

| Pitch (P) | 12.70 |

| Internal width | 3.4 |

| Roller Φ (Dr) | 7.75 |

|

Type |

Teeth |

Do |

Dp |

Bored |

Wt kg |

Material |

|

|

Stock |

Min |

||||||

| K410A |

8 |

38 |

33.19 |

10 |

12 |

0.01 |

C45 Solid |

|

9 |

42 |

37.13 |

10 |

12 |

0.02 |

||

|

10 |

46 |

41.10 |

11 |

13 |

0.05 |

||

|

11 |

51 |

45.08 |

12 |

14 |

0.09 |

||

|

12 |

55 |

49.07 |

12 |

14 |

0.10 |

||

|

13 |

59 |

53.07 |

15 |

17 |

0,12 |

||

|

14 |

63 |

57.07 |

15 |

17 |

0.14 |

||

|

IS |

67 |

61.08 |

15 |

17 |

0.16 |

||

|

16 |

71 |

65.10 |

15 |

17 |

0.18 |

||

|

17 |

76 |

69.12 |

15 |

17 |

0.20 |

||

|

18 |

80 |

73.14 |

15 |

17 |

0.23 |

||

|

19 |

84 |

77.16 |

15 |

17 |

0.26 |

||

|

20 |

88 |

81.18 |

16 |

18 |

0.29 |

||

|

21 |

92 |

85.21 |

16 |

18 |

0.30 |

||

|

22 |

96 |

89.24 |

16 |

18 |

0.35 |

||

|

23 |

100 |

93.27 |

16 |

18 |

0.38 |

||

|

24 |

104 |

9730 |

16 |

18 |

0.40 |

||

|

25 |

108 |

101.33 |

16 |

18 |

0.45 |

||

|

26 |

112 |

105.36 |

16 |

18 |

0.49 |

||

|

27 |

116 |

109.40 |

16 |

18 |

0.50 |

||

|

28 |

120 |

113.43 |

16 |

18 |

0.56 |

||

|

29 |

124 |

117.46 |

16 |

18 |

0.60 |

||

|

30 |

128 |

12L50 |

16 |

18 |

0.63 |

||

|

31 |

133 |

125.53 |

16 |

18 |

0.65 |

||

|

32 |

137 |

129.57 |

16 |

18 |

0.70 |

||

|

33 |

141 |

133.61 |

16 |

18 |

0.75 |

||

|

34 |

145 |

137.64 |

16 |

18 |

0.80 |

||

|

35 |

149 |

141.68 |

16 |

18 |

0.85 |

||

|

36 |

153 |

145.72 |

18 |

20 |

0.90 |

||

|

37 |

157 |

149.75 |

18 |

20 |

0.99 |

||

|

38 |

161 |

153.79 |

18 |

20 |

1.00 |

||

|

39 |

165 |

157.83 |

18 |

20 |

1.18 |

||

|

40 |

169 |

161.87 |

18 |

20 |

1.20 |

||

|

41 |

173 |

165.91 |

18 |

20 |

1.20 |

||

|

42 |

177 |

169.94 |

18 |

20 |

1.25 |

||

|

44 |

185 |

178.02 |

18 |

20 |

135 |

||

|

45 |

189 |

182.06 |

18 |

20 |

1.40 |

||

|

46 |

193 |

186.10 |

18 |

20 |

1.49 |

||

|

47 |

197 |

190.14 |

18 |

20 |

1.58 |

||

|

48 |

201 |

194.18 |

18 |

20 |

1.63 |

||

|

49 |

205 |

198.22 |

18 |

20 |

1.73 |

||

|

50 |

209 |

202.26 |

18 |

20 |

1.80 |

||

|

52 |

218 |

210.34 |

18 |

20 |

1.93 |

||

|

54 |

226 |

Z18-42 |

18 |

20 |

2.00 |

||

|

60 |

250 |

242.66 |

18 |

20 |

2.60 |

||

K40A

| SPROCKETS | mm |

| Tooth width (T) | 7.2 |

| CHAIN | mm |

| Pitch (P) | 12.7 |

| Internal width | 7.95 |

| Roller Φ (Dr) | 7.95 |

|

Type |

Teeth |

Do |

Dp |

Bored Stock |

Min |

Wt kg |

Material |

|

K4OA |

10 |

46 |

41.10 |

9.5 |

115 |

0.05 |

C45 Solid |

|

11 |

51 |

45.08 |

10.5 |

12.5 |

0.09 |

||

|

12 |

55 |

49.07 |

11.5 |

13.5 |

0.10 |

||

|

13 |

59 |

53.07 |

13.5 |

15-5 |

0.12 |

||

|

14 |

63 |

57.07 |

13.5 |

15.5 |

0.14 |

||

|

15 |

67 |

61.08 |

13.5 |

15.5 |

0J6 |

||

|

16 |

71 |

65.10 |

13.5 |

15.5 |

0.18 |

||

|

17 |

76 |

69.12 |

13.5 |

15,5 |

0.20 |

||

|

18 |

80 |

73.14 |

13-5 |

15,5 |

0.23 |

||

|

19 |

84 |

77.16 |

13.5 |

15.5 |

0.26 |

||

|

20 |

88 |

81.18 |

14 |

16 |

0.29 |

||

|

21 |

92 |

85.21 |

14 |

16 |

0.30 |

||

|

22 |

96 |

89.24 |

14 |

16 |

0.35 |

||

|

23 |

100 |

93.27 |

14 |

16 |

0.38 |

||

|

24 |

104 |

97.30 |

14 |

16 |

0.40 |

||

|

25 |

108 |

101.33 |

14 |

16 |

0.45 |

||

|

26 |

112 |

105.36 |

14 |

16 |

0.49 |

||

|

27 |

116 |

109.40 |

14 |

16 |

0.50 |

||

|

28 |

120 |

113.43 |

14 |

16 |

0.56 |

||

|

29 |

124 |

117.46 |

14 |

16 |

0.60 |

||

|

30 |

128 |

121.50 |

14 |

16 |

0.63 |

||

|

31 |

133 |

125.53 |

14 |

16 |

0.65 |

||

|

32 |

137 |

129.57 |

14 |

16 |

0.70 |

||

|

33 |

141 |

133.61 |

14 |

16 |

0.75 |

||

|

34 |

145 |

137.64 |

14 |

16 |

0-80 |

||

|

35 |

149 |

141,68 |

14 |

16 |

0.85 |

||

|

36 |

153 |

145.72 |

16 |

18 |

0.90 |

||

|

37 |

157 |

149.75 |

16 |

18 |

0.99 |

||

|

38 |

161 |

153.79 |

16 |

18 |

1.00 |

||

|

39 |

165 |

157.83 |

16 |

18 |

1.15 |

||

|

40 |

169 |

161.87 |

16 |

18 |

1.20 |

||

|

41 |

173 |

165.91 |

16 |

18 |

1.20 |

||

|

42 |

177 |

169.95 |

16 |

18 |

1.25 |

||

|

43 |

181 |

173.98 |

16 |

18 |

1.30 |

||

|

44 |

185 |

178.02 |

16 |

18 |

1.35 |

||

|

45 |

189 |

182.06 |

16 |

18 |

1.40 |

||

|

46 |

193 |

186.10 |

16 |

18 |

1.49 |

||

|

47 |

197 |

190.14 |

16 |

18 |

1.58 |

||

| 48 |

201 |

194.18 |

16 |

18 |

1-63 |

||

|

49 |

205 |

198.22 |

16 |

18 |

1.73 |

||

|

50 |

209 |

202.26 |

16 |

18 |

1.80 |

||

|

51 |

214 |

206.30 |

16 |

18 |

1.88 |

||

|

52 |

218 |

210.34 |

16 |

18 |

1.93 |

||

|

53 |

222 |

214.38 |

16 |

18 |

1.98 |

||

|

54 |

226 |

218.42 |

16 |

18 |

2.00 |

||

|

S5 |

230 |

222.46 |

16 |

18 |

2.18 |

||

|

56 |

234 |

226.50 |

16 |

18 |

2.26 |

||

|

58 |

242 |

234.58 |

16 |

18 |

2.43 |

||

|

59 |

246 |

238.62 |

16 |

18 |

2.51 |

||

|

60 |

250 |

242,66 |

16 |

18 |

2.60 |

||

|

62 |

258 |

250.74 |

16 |

18 |

2.77 |

||

|

64 |

266 |

258.83 |

16 |

18 |

2.90 |

||

|

65 |

270 |

262.87 |

16 |

18 |

3.00 |

||

|

68 |

282 |

274.99 |

16 |

18 |

3.35 |

||

|

70 |

290 |

283.07 |

16 |

18 |

3.50 |

||

|

72 |

299 |

291.16 |

20 |

22 |

370 |

||

|

75 |

311 |

303,28 |

20 |

22 |

4.00 |

||

|

80 |

331 |

323.49 |

20 |

22 |

4.60 |

||

|

85 |

351 |

343.69 |

20 |

22 |

5.20 |

||

|

90 |

371 |

363.90 |

20 |

22 |

5.80 |

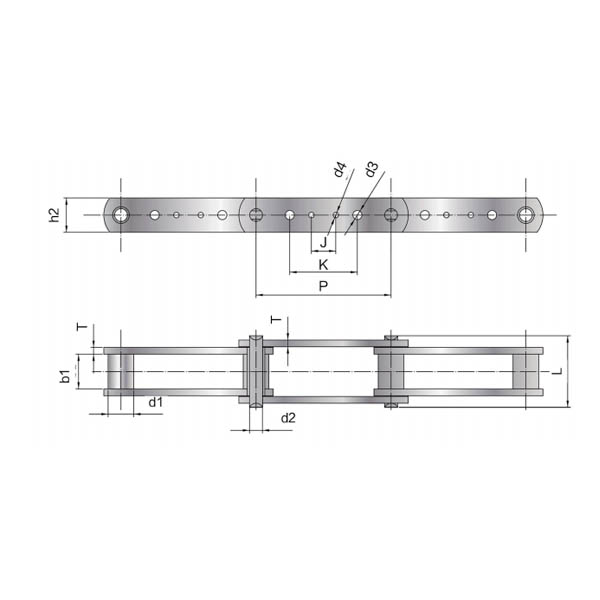

Plate wheel:

The plate wheel helps to determine the performance and service life of the chain

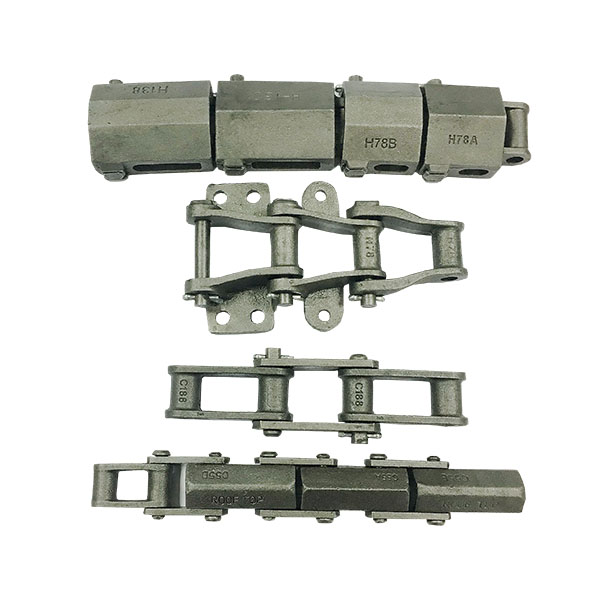

Plate wheels help determine the performance and service life of the chain, so GL provides appropriate corresponding plate wheels from its extensive inventory of all chains. This ensures proper alignment between the chain and the plate wheels and prevents fit differences that can affect the overall life of the chain drive. GL also manufactures the sprockets and plate wheels from solid materials or welded material exactly as the customer requires. GL offers a variety of tooth shapes and material options with or without hardened teeth. Designs include simplex, duplex, triplex and cast iron. European standard / AMERICA standard / Asian standard are avilable.

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for OEM/ODM China Double Pitch Roller Chain Sprockets - Platewheels per Asian Standard – GOODLUCK , The product will supply to all over the world, such as: Seychelles, Barbados, Ghana, Our factory insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thanks for all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.Thanks.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.