Professional China Cast Iron Sprockets - Finished Bore Sprockets per European Standard – GOODLUCK

Professional China Cast Iron Sprockets - Finished Bore Sprockets per European Standard – GOODLUCK Detail:

Finished Bore Sprockets European Standard Series

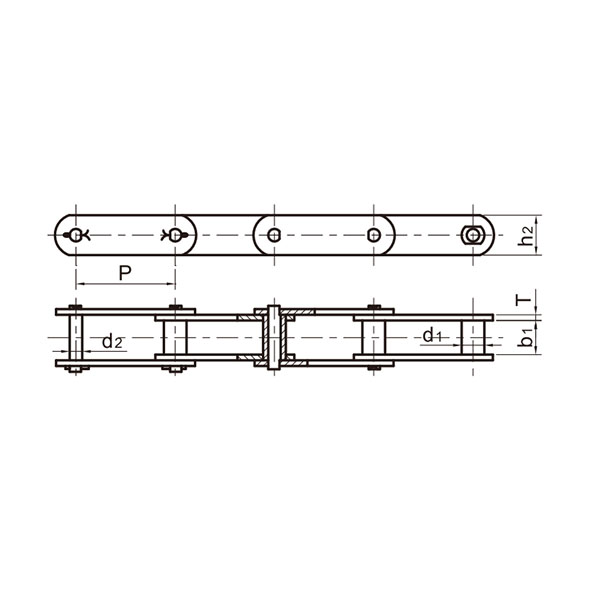

For Roller Chains DIN 8187TSO/R 606

All sprockets are finished with induction hardened teeth.

This treatment gives a longer lasting life to sprockets.

And with finished bore,keyway and 2 grub Screws,this eliminates further modification by customer and can be fitted immediately.

Bore-Keyway—Screws

|

D(H7) |

B(H9) |

T |

M |

|

10 |

4 |

D+1.8 (+0.1/0) |

M3 |

|

11 |

4 |

D+1.8 (+0.1/0) |

M3 |

|

12 |

4 |

D+1.8 (+0.1/0) |

M3 |

|

14 |

5 |

D+2.3 (+0.1/0) |

M4 |

|

16 |

5 |

D+2.3 (+0.1/0) |

M4 |

|

18 |

6 |

D+2.8 (+0.1/0) |

M5 |

|

19 |

6 |

D + 2.8 (+0.1/0) |

M5 |

|

20 |

6 |

D+2.8 (+0.1/0) |

M5 |

|

22 |

6 |

D+2.8 (+0.1/0) |

M5 |

|

24 |

8 |

D + 3.3 (+0.2/0) |

M6 |

|

25 |

8 |

D + 3.3 (+0.2/0) |

M6 |

|

28 |

8 |

D+3.3 (+0.2/0) |

M6 |

|

30 |

8 |

D+3.3 (+0.2/0) |

M6 |

|

32 |

10 |

D+3.3 (+0.2/0) |

M8 |

|

35 |

10 |

D+3.3 (+0.2/0) |

M8 |

|

38 |

10 |

D + 3.3 (+0.2/0) |

M8 |

|

40 |

12 |

D + 3.3 (+0.2/0) |

M10 |

|

42 |

12 |

D+3.3 (+0.2/0) |

M10 |

|

45 |

14 |

D+3.8 (+0.2/0) |

M12 |

|

48 |

14 |

D+3.8 (+0.2/0) |

M12 |

|

50 |

14 |

D+3.8 (+0.2/0) |

M12 |

|

60 |

18 |

D+4.4 (+0.2/0) |

M12 |

|

65 |

18 |

D+4.4 (+0.2/0) |

M12 |

|

70 |

20 |

D+4.9 (+0.2/0) |

M12 |

Material:C45

|

z |

d |

dp |

D |

H |

d |

z |

de |

dP |

D |

H |

d |

z |

de |

dP |

D |

H |

d |

|

10 |

34 |

30.80 |

10 |

22 |

24 |

16 |

22 |

37 |

20 |

64.3 |

60.89 |

24 |

28 |

46 |

|||

|

11 |

52.3 |

48.82 |

24 |

16 |

25 |

||||||||||||

|

12 |

26 |

25 |

42 |

16 |

|||||||||||||

|

14 |

29 |

17 |

12 |

18 |

|||||||||||||

|

11 |

37 |

33.8 |

10 |

25 |

24 |

14 |

19 |

||||||||||

|

12 |

26 |

16 |

21 |

68 |

63.91 |

20 |

28 |

48 |

|||||||||

|

14 |

29* |

18 |

40 |

22 |

|||||||||||||

|

16 |

31* |

55.3 |

51.83 |

19 |

28 |

24 |

|||||||||||

|

12 |

40 |

36.8 |

10 |

25 |

25 |

18 |

20 |

25 |

|||||||||

|

12 |

26 |

22 |

16 |

||||||||||||||

|

14 |

29* |

24 |

18 |

||||||||||||||

|

16 |

31* |

25 |

42 |

19 |

|||||||||||||

|

13 |

43 |

39.8 |

10 |

25 |

28 |

12 |

22 |

71 |

66.93 |

20 |

28 |

50 |

|||||

|

12 |

14 |

22 |

|||||||||||||||

|

14 |

29 |

16 |

24 |

||||||||||||||

|

16 |

31 |

18 |

25 |

||||||||||||||

|

18 |

35* |

18 |

58.3 |

54.85 |

19 |

28 |

43 |

16 |

|||||||||

|

14 |

46.3 |

42.8 |

12 |

20 |

18 |

||||||||||||

|

14 |

25 |

31 |

22 |

19 |

|||||||||||||

|

16 |

24 |

23 |

73.5 |

69.95 |

20 |

28 |

52 |

||||||||||

|

18 |

35 |

25 |

22 |

||||||||||||||

|

19 |

12 |

24 |

|||||||||||||||

|

15 |

49.3 |

45.81 |

12 |

14 |

25 |

||||||||||||

|

14 |

25 |

34 |

16 |

16 |

|||||||||||||

|

16 |

18 |

18 |

|||||||||||||||

|

18 |

19 |

61.3 |

57.87 |

19 |

28 |

45 |

19 |

||||||||||

|

19 |

35 |

20 |

24 |

77 |

72.97 |

20 |

28 |

54 |

|||||||||

|

20 |

36 |

22 |

22 |

||||||||||||||

|

22 |

38 |

24 |

24 |

||||||||||||||

|

24 |

42* |

25 |

25 |

||||||||||||||

|

25 |

12 |

16 |

|||||||||||||||

| 16 | 52.3 | 48.82 |

12 |

28 |

14 |

18 |

|||||||||||

|

14 |

16 |

19 |

|||||||||||||||

|

16 |

20 |

64.3 |

60.89 |

18 |

28 |

46 |

25 |

80 |

76 |

20 |

28 |

57 |

|||||

|

18 |

37 |

19 |

22 |

||||||||||||||

|

19 |

20 |

24 |

|||||||||||||||

|

20 |

22 |

25 |

Material:C45

|

z |

de |

dp |

D |

H |

d |

z |

dc |

dP |

D |

H |

d |

Z |

de |

dp |

D |

H |

d |

z |

de |

dP |

D |

H |

d |

|

12 |

26 |

18 |

18 |

77.8 |

73.14 |

38 |

28 |

56 |

20 |

||||||||||||||

|

10 |

45.2 |

41.1 |

14 |

25 |

29 |

19 |

16 |

22 |

|||||||||||||||

|

16 |

31 |

20 |

18 |

24 |

|||||||||||||||||||

|

12 |

22 |

45 |

19 |

25 |

|||||||||||||||||||

|

14 |

15 |

65.5 |

61.09 |

24 |

28 |

20 |

22 |

93.8 |

89.24 |

28 |

28 |

70 |

|||||||||||

|

11 |

48.7 |

45.07 |

16 |

25 |

31 |

25 |

22 |

30 |

|||||||||||||||

|

18 |

34 |

28 |

24 |

32 |

|||||||||||||||||||

|

19 |

81.7 |

77.16 |

28 |

60 |

|||||||||||||||||||

|

19 |

35 |

30 |

47 |

25 |

35 |

||||||||||||||||||

|

12 |

32 |

49 |

28 |

38 |

|||||||||||||||||||

|

14 |

16 |

30 |

19 |

||||||||||||||||||||

|

33 |

|||||||||||||||||||||||

|

16 |

18 |

32 |

20 |

||||||||||||||||||||

|

18 |

19 |

35 |

22 |

||||||||||||||||||||

|

12 |

53 |

49.07 |

19 |

28 |

35 |

20 |

38 |

24 |

|||||||||||||||

|

20 |

36 |

22 |

50 |

16 |

25 |

||||||||||||||||||

|

16 |

69.5 |

65.1 |

28 |

23 |

98.2 |

93.27 |

28 |

70 |

|||||||||||||||

|

22 |

38 |

24 |

18 |

28 |

|||||||||||||||||||

|

24 |

41* |

25 |

19 |

30 |

|||||||||||||||||||

|

25 |

42* |

28 |

20 |

32 |

|||||||||||||||||||

|

12 |

30 |

22 |

35 |

||||||||||||||||||||

|

14 |

32 |

53 |

24 |

38 |

|||||||||||||||||||

|

20 |

85.8 |

81.19 |

28 |

64 |

|||||||||||||||||||

|

16 |

16 |

25 |

19 |

||||||||||||||||||||

|

18 |

37 |

18 |

28 |

20 |

|||||||||||||||||||

|

19 |

19 |

30 |

22 |

||||||||||||||||||||

|

57.4 |

53.06 |

28 |

|||||||||||||||||||||

|

20 |

20 |

32 |

24 |

||||||||||||||||||||

|

22 |

22 |

35 |

25 |

||||||||||||||||||||

|

17 |

73.6 |

69.11 |

28 |

52 |

24 |

101.8 |

97.29 |

28 |

70 |

||||||||||||||

|

24 |

24 |

38 |

28 |

||||||||||||||||||||

|

42 |

|||||||||||||||||||||||

|

25 |

25 |

16 |

30 |

||||||||||||||||||||

|

28 |

45* |

28 |

18 |

32 |

|||||||||||||||||||

|

12 |

30 |

19 |

35 |

||||||||||||||||||||

|

14 |

32 |

20 |

38 |

||||||||||||||||||||

|

16 |

16 |

22 |

19 |

||||||||||||||||||||

|

18 |

18 |

24 |

20 |

||||||||||||||||||||

|

21 |

89.7 |

85.22 |

28 |

68 |

|||||||||||||||||||

|

19 |

41 |

19 |

25 |

22 |

|||||||||||||||||||

|

14 |

61.8 |

57.07 |

28 |

||||||||||||||||||||

|

20 |

20 |

28 |

24 |

||||||||||||||||||||

|

22 |

22 |

30 |

25 |

||||||||||||||||||||

|

24 |

18 |

77.8 |

73.14 |

24 |

28 |

56 |

32 |

25 |

105.8 |

101.33 |

28 |

28 |

70 |

||||||||||

|

25 |

25 |

35 |

30 |

||||||||||||||||||||

|

28 |

45 |

28 |

38 |

32 |

|||||||||||||||||||

|

12 |

30 |

16 |

35 |

||||||||||||||||||||

|

15 |

65.5 |

61.09 |

14 |

28 |

45 |

32 |

22 |

93.8 |

89.24 |

18 |

28 |

70 |

38 |

||||||||||

|

16 |

35 |

19 |

Because these Type B sprockets are manufactured in quantity, they are more economical to purchase than the re-machining of stock-bore sprockets, with re-boring, and installing the keyway and setscrews. Finished Bore sprockets are available for Standard “B” Type where the hub protrudes on one side. The Type B Sprockets are also available in a variety of materials. We have access and can quote you Stainless “B” Type, Double Pitch “B” Type, Single Type “B” Double sprockets and Metric Type “B”.

Keyway is on “center line of tooth” so the sprockets are timed and will run together or as sets.

Our Finished Bore Type B Sprockets are ready for immediate installation. These are used with our Roller Chain.

The Sprockets are completely finished to the bore of the shaft diameter requirement and have a keyway and set screws. The exception to this is some of the ½” bore Type B sprockets do not have a keyway.

Product detail pictures:

Related Product Guide:

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for Professional China Cast Iron Sprockets - Finished Bore Sprockets per European Standard – GOODLUCK , The product will supply to all over the world, such as: Malaysia, Iraq, Iceland, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.