Professional Design Couplings - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK

Professional Design Couplings - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK Detail:

GE COUPLINGS (AL, CAST)

|

GE(AL-H) |

|||||||||||||||||

|

ITEM |

PART |

(Nm) |

size(mm) |

||||||||||||||

|

d(min-max) |

Overall dimensions |

Set screw |

|||||||||||||||

|

92 Sh A |

98 Sh A |

64 Sh D |

L |

l1;l2 |

E |

b |

s |

DH |

dH |

D ; D1 |

N |

G |

t |

TA(Nm) |

|||

|

14 |

1a |

7.5 |

12.5 |

- |

6-16 |

35 |

11 |

13 |

10 |

1.5 |

30 |

10 |

30 |

- |

M4 |

5 |

1.5 |

|

19 |

1 |

10 |

17 |

- |

6-19 |

66 |

25 |

16 |

12 |

2 |

40 |

18 |

32 |

20 |

M5 |

10 |

2 |

|

1a |

19-24 |

40 |

|||||||||||||||

|

24 |

1 |

35 |

60 |

- |

9-24 |

78 |

30 |

18 |

14 |

2 |

55 |

27 |

40 |

24 |

M5 |

10 |

2 |

|

1a |

22-28 |

55 |

|||||||||||||||

|

28 |

1 |

95 |

160 |

- |

10-28 |

90 |

35 |

20 |

15 |

2.5 |

65 |

30 |

48 |

28 |

M8 |

15 |

10 |

|

1a |

28-38 |

65 |

|||||||||||||||

GE EN-GJL-250 ( GG 25 )

|

1 |

12-38 |

66 |

|||||||||||||||

|

38 |

1a |

190 |

325 |

405 |

38-45 |

114 |

45 |

24 |

18 |

3 |

80 |

38 |

37 |

M8 |

15 |

10 |

|

|

1b |

12-45 |

164 |

70 |

62 |

|||||||||||||

|

1 |

14-42 |

75 |

|||||||||||||||

|

42 |

1a |

265 |

450 |

560 |

42-55 |

126 |

50 |

26 |

20 |

3 |

95 |

46 |

94 |

40 |

M8 |

20 |

10 |

|

1b |

14-55 |

176 |

75 |

65 |

|||||||||||||

|

1 |

15-48 |

85 |

|||||||||||||||

|

48 |

1a |

310 |

525 |

655 |

48-60 |

140 |

56 |

28 |

21 |

3.5 |

105 |

51 |

45 |

M8 |

20 |

10 |

|

|

1b |

15-60 |

188 |

80 |

69 |

|||||||||||||

|

1 |

20-55 |

98 |

|||||||||||||||

|

55 |

1a |

410 |

685 |

825 |

55-70 |

160 |

65 |

30 |

22 |

4 |

120 |

60 |

118 |

M10 |

20 |

17 |

|

|

1b |

20-70 |

210 |

90 |

120 |

- |

||||||||||||

|

1 |

22-65 |

115 |

61 |

||||||||||||||

|

65 |

1a |

625 |

940 |

1175 |

65-80 |

185 |

75 |

35 |

26 |

4.5 |

135 |

68 |

M10 |

20 |

17 |

||

|

1b |

22-80 |

235 |

100 |

||||||||||||||

|

1 |

30-75 |

135 |

69 |

||||||||||||||

|

75 |

1a |

1280 |

1920 |

2400 |

75-95 |

210 |

85 |

40 |

30 |

5 |

160 |

80 |

1RQ |

M10 |

25 |

17 |

|

|

1b |

30-95 |

260 |

110 |

||||||||||||||

|

1 |

40-90 |

160 |

81 |

||||||||||||||

|

90 |

1a |

2400 |

3600 |

4500 |

90-110 |

245 |

100 |

45 |

34 |

5.5 |

200 |

100 |

M12 |

30 |

40 |

||

|

1b |

40-110 |

295 |

125 |

GE EN-GJL-400-15 ( GGg 40 )

|

100 |

1 |

3300 |

4950 |

6185 |

50-115 |

270 |

110 |

50 |

38 |

6 |

225 |

113 |

180 |

89 |

M12 |

30 |

40 |

|

110 |

1 |

4800 |

7200 |

9000 |

60-125 |

295 |

120 |

55 |

42 |

6.5 |

255 |

127 |

200 |

96 |

M16 |

35 |

80 |

|

125 |

1 |

6650 |

10000 |

12500 |

60-145 |

340 |

140 |

60 |

46 |

7 |

290 |

147 |

230 |

112 |

M16 |

40 |

80 |

|

140 |

1 |

8550 |

12800 |

16000 |

60-160 |

375 |

155 |

65 |

50 |

7.5 |

320 |

165 |

255 |

124 |

M20 |

45 |

140 |

|

160 |

1 |

12800 |

19200 |

24000 |

80-185 |

425 |

175 |

75 |

57 |

9 |

370 |

190 |

290 |

140 |

M20 |

50 |

140 |

|

180 |

1 |

18650 |

28000 |

35000 |

85-200 |

475 |

185 |

85 |

64 |

10.5 |

420 |

220 |

325 |

156 |

M20 |

50 |

140 |

|

GE (STEEL) |

|||||||||||||||||

|

ITEM |

PART |

(Nm) |

SIZE (mm) |

||||||||||||||

|

d(min-max) |

Overall dimensions |

Special dimensions of steel sleeve |

Set screw |

||||||||||||||

|

92 Sh A |

98 Sh A |

64 Sh D |

L |

E |

b |

s |

DH |

dh |

D;D1 |

N |

G |

t |

TA(Nm) |

||||

|

14 |

1a |

7.5 |

12.5 |

16 |

0-16 |

35 |

11 |

13 |

10 |

1.5 |

30 |

10 |

30 |

- |

M4 |

5 |

1.5 |

|

1b |

50 |

18.5 |

|||||||||||||||

|

19 |

1a |

10 |

17 |

21 |

0-25 |

66 |

25 |

16 |

12 |

2 |

40 |

18 |

40 |

M5 |

10 |

2 |

|

|

1b |

90 |

37 |

|||||||||||||||

|

24 |

1a |

35 |

60 |

75 |

0-35 |

78 |

30 |

18 |

14 |

2 |

55 |

27 |

55 |

M5 |

10 |

2 |

|

|

1b |

118 |

50 |

|||||||||||||||

|

28 |

1a |

95 |

160 |

200 |

0-40 |

90 |

35 |

20 |

15 |

2.5 |

65 |

30 |

65 |

- |

M8 |

15 |

10 |

|

1b |

140 |

60 |

|||||||||||||||

|

38 |

1 |

190 |

325 |

405 |

0-48 |

114 |

45 |

24 |

18 |

3 |

80 |

38 |

70 |

27 |

M8 |

15 |

10 |

|

1b |

164 |

70 |

85 |

- |

|||||||||||||

|

42 |

1 |

265 |

450 |

560 |

0-55 |

126 |

50 |

26 |

20 |

3 |

95 |

46 |

85 |

28 |

M8 |

20 |

10 |

|

1b |

176 |

75 |

95 |

- |

|||||||||||||

|

48 |

1 |

310 |

525 |

655 |

0-62 |

140 |

56 |

28 |

21 |

3.5 |

105 |

51 |

95 |

32 |

M8 |

20 |

10 |

|

1b |

188 |

80 |

105 |

- |

|||||||||||||

|

55 |

1 |

410 |

685 |

825 |

0-74 |

160 |

65 |

30 |

22 |

4 |

120 |

60 |

110 |

37 |

M10 |

20 |

17 |

|

1b |

210 |

90 |

120 |

- |

|||||||||||||

|

65 |

1 |

625 |

940 |

1175 |

0-80 |

185 |

75 |

35 |

26 |

4.5 |

135 |

68 |

115 |

47 |

M10 |

20 |

17 |

|

1b |

235 |

100 |

135 |

- |

|||||||||||||

|

75 |

1 |

1280 |

1920 |

2400 |

0-95 |

210 |

85 |

40 |

30 |

5 |

160 |

80 |

135 |

53 |

M10 |

25 |

17 |

|

1b |

260 |

110 |

160 |

- |

|||||||||||||

|

90 |

1 |

2400 |

3600 |

4500 |

0-110 |

245 |

100 |

45 |

34 |

5.5 |

200 |

100 |

160 |

62 |

M12 |

30 |

40 |

|

1b |

295 |

125 |

200 |

- |

|||||||||||||

GE(GG25)

|

ITEM |

TB |

size(mm) |

Mounting screw of shaft sleeve |

|||||||||||

|

l1;l2 |

E |

S |

b |

L |

N |

DH |

D1 |

dH |

Specification |

length |

number |

TA (Nm) |

||

|

24 |

1008 |

23 |

18 |

2.0 |

14 |

64 |

一 |

55 |

55 |

27 |

1/4 |

13 |

2 |

5.7 |

|

28 |

1108 |

23 |

20 |

2.5 |

15 |

66 |

一 |

65 |

65 |

30 |

1/4” |

13 |

2 |

5.7 |

|

38 |

1108 |

23 |

24 |

3.0 |

18 |

70 |

15 |

80 |

78 |

38 |

1/4” |

13 |

2 |

5.7 |

|

42 |

1610 |

26 |

26 |

3.0 |

20 |

78 |

16 |

95 |

94 |

46 |

3/8” |

16 |

2 |

20 |

|

48 |

1615 |

39 |

28 |

3.5 |

21 |

106 |

28 |

105 |

104 |

51 |

3/8“ |

16 |

2 |

20 |

|

55 |

2012 |

33 |

30 |

4.0 |

22 |

96 |

20 |

120 |

118 |

60 |

7/16” |

22 |

2 |

31 |

|

65 |

2012 |

33 |

35 |

4.5 |

26 |

101 |

19 |

135 |

115 |

68 |

7/16” |

22 |

2 |

31 |

|

2517 |

1/2” |

25 |

49 |

|||||||||||

|

75 |

. 3020 |

52 |

40 |

5.0 |

30 |

144 |

36 |

160 |

158 |

80 |

5/8″ |

32 |

2 |

92 |

|

90 |

3020 |

52 |

45 |

5.5 |

24 |

144 |

33 |

200 |

160 |

100 |

5/8“ |

32 |

2 |

92 |

|

125 |

3535 |

90 |

60 |

147 |

1/2” |

3 |

113 |

|||||||

|

4545 |

114 |

3/4″ |

49 |

192 |

||||||||||

*ONLY FOR H TYPE *BSW SCREW

|

Cone sleeve |

|||||||||||||||||||

|

Specification |

The tolerance of finished hole diameter D1 can be H7 keyway according to DIN 6885 / 1 |

||||||||||||||||||

|

1008 |

10 |

11 |

12 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

||||||||

|

1108 |

10 |

11 |

12 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28* |

|||||||

|

1610 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42* |

||||

|

1615 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42* |

||||

|

2012 |

14 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

|

|

2517 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

|

3020 |

25 |

28 |

30 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

65 |

70 |

75 |

||||

|

3535 |

35 |

38 |

40 |

42 |

45 |

48 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

||||

|

4545 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

100 |

105 |

110 |

|||||||

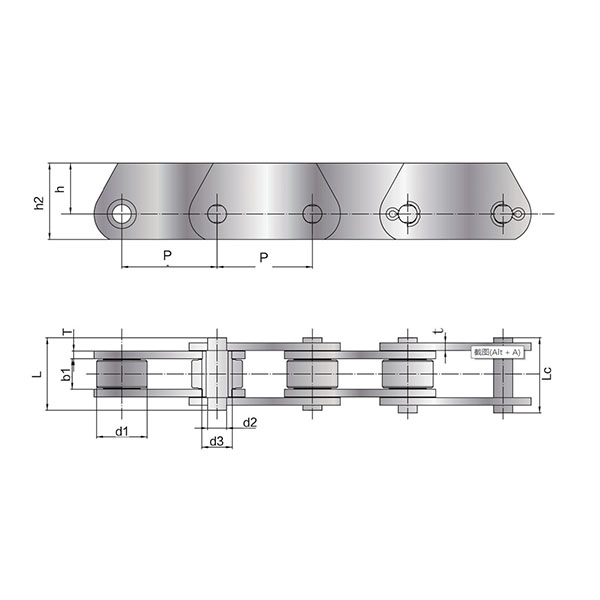

GL GE couplings are designed to transmit torque between drive and driven components with zero‑backlash via curved jaw hubs and elastomeric elements, commonly known as spiders. The combination of these components provides dampening and accommodation of misalignment. This product is available in a variety of metals, elastomers and mounting configurations to meet your specific needs. GL GS couplings suitable for horizontal or vertical applications are constructed from a variety of materials, providing a torsionally flexible zero‑backlash platform optimizing the balance between inertia, coupling performance and application requirements. The machined concaved jaws provide a pocket to preload the spider legs, allowing the spiders to articulate freely while accommodating misalignment, minimizing restoring forces, dampen shock and vibration, while providing failsafe zero‑backlash torque transmission. The symmetrical relationship of the hubs allows for a variety of accessories to accommodate different shaft distances.

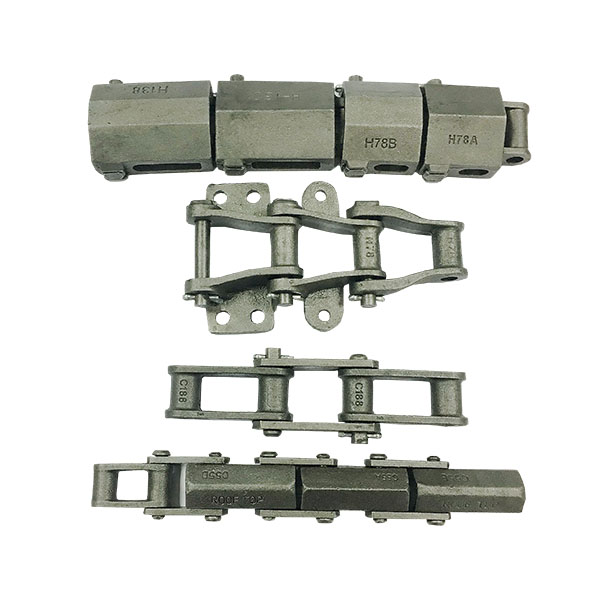

Product detail pictures:

Related Product Guide:

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Professional Design Couplings - GE Couplings, Type 1/1, 1a/1a, 1b/1b in AL/Cast/Steel – GOODLUCK , The product will supply to all over the world, such as: UK, Kyrgyzstan, Stuttgart, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!