Quality Inspection for Rm Couplings - Oldham Couplings, Body AL, Elastic PA66 – GOODLUCK

Quality Inspection for Rm Couplings - Oldham Couplings, Body AL, Elastic PA66 – GOODLUCK Detail:

|

Dimension table |

mm |

|||||||

|

Model |

Common DL / D2 inner diameter size |

ΦD |

L |

LF |

LP |

F |

M |

Tightening torque (n.m) |

|

GL-16X18 |

4-5-6-6.35-7-8 |

16 |

18 |

7.1 |

12 |

3.0 |

M3 |

1.2 |

|

GL-20X23 |

5-6-6.35-7-8 |

20 |

23 |

9 |

12.7 |

4.5 |

M4 |

1.7 |

|

GL-20X25 |

5-6-6.35-8-9-9.525-10 |

20 |

25 |

10.1 |

12.7 |

3.0 |

M4 |

2.5 |

|

GL-25X28 |

5-6-8-9-9.525-10-11-12-14 |

25 |

28 |

21 |

17.7 |

2.8 |

M4 |

2.5 |

|

GL-32X33 |

5-6-8-9-9.525-10-11-12-12.7-14-15-16 |

32 |

33 |

14 |

20 |

3.4 |

M4 |

2.5 |

|

GL-40X32 |

8-9-9.525-10-11-12-12.7-14-15-16-17-18-19-20 |

40 |

32 |

14 |

20.3 |

3.2 |

M4 |

2.5 |

|

GL-44X46 |

8-9-9.525-10-11-1212.7-14-15-16-17-18-19-20-22 |

44 |

46 |

20.7 |

18.4 |

3.5 |

M5 |

5 |

|

GL-50X38 |

10-12-12.7-14-15-16-17-18-19-20-22-24-25 |

50 |

38 |

16.5 |

22.35 |

3.8 |

M5 |

5 |

|

GL-55X57 |

10-12-12.7-14-15-16-17-18-19-20-22-24-25-28-30-32 |

55 |

57 |

26.2 |

25.8 |

7.8 |

M5 |

5 |

|

GL-63X47 |

14-15-16-17-18-19-20-22-24-25-28-30-32 |

63 |

47 |

21 |

25.8 |

6.0 |

M6 |

8 |

|

GL-70X77 |

16-17-18-19-20-22-24-25-28-30-32-25-38-40 |

70 |

77 |

37 |

25 |

13.5 |

M8 |

20 |

Technical parameter

|

Technical parameter |

mm |

|||||||

|

Model |

Rated torque (N.m) |

Allowable eccentricity (mm) |

Allowable deflection angle (∠。) |

Allowable axial deviation (mm) |

Allowable speed (RPM) |

Static torsional stiffness (N.m/rad) |

Moment of inertia (N.m) |

Coupling weight (g) |

|

GL-16X18 |

0.7 |

0.8 |

3 |

±0.2 |

9000 |

30 |

3.0X10-7 |

6 |

|

GL-20X23 |

1.2 |

1.5 |

3 |

±0.2 |

3100 |

60 |

1.0X10-6 |

14 |

|

GL-20X25 |

1.25 |

1.2 |

3 |

±0.2 |

7000 |

58 |

3.0X10-7 |

18 |

|

GL-25X28 |

2 |

1.6 |

3 |

±0.2 |

6000 |

130 |

2.8X10-6 |

25 |

|

GL-32X33 |

4.5 |

2 |

3 |

±0.2 |

4800 |

270 |

8.9X10-5 |

44 |

|

GL-40X32 |

9 |

2.4 |

3 |

±0.2 |

3600 |

520 |

2.1X10-5 |

81 |

|

GL-44X46 |

12 |

2.8 |

3 |

±0.2 |

3500 |

560 |

3.8X10-5 |

136 |

|

GL-50X38 |

19 |

2.6 |

3 |

±0.2 |

3000 |

800 |

6.0X10-5 |

142 |

|

GL-55X57 |

22 |

3.3 |

3 |

±0.2 |

2800 |

795 |

9.9X10-5 |

255 |

|

GL-63X47 |

33 |

3 |

3 |

±0.2 |

2500 |

1200 |

2.1X10-4 |

320 |

|

GL-70X77 |

56 |

3.8 |

3 |

±0.2 |

2500 |

1260 |

3.9X10-4 |

445 |

Comparison table of keyway processing dimensions

|

Shaft diameter dimension |

Standard machining dimension of keyway |

Keyway size |

Standard drawing of keyway processing |

|||

|

dl/d2 |

b |

t |

(bxh) |

|

||

|

Slot width |

tolerance |

slot depth |

tolerance |

|||

|

Φ6-Φ7.9 |

2 |

±0.0125 |

1.0 |

±0.10 |

2X2 |

|

|

Φ8-Φ10 |

3 |

±0.0150 |

1.4 |

3X3 |

||

|

Φ10.1-Φ12 |

4 |

1.8 |

4X4 |

|||

|

Φ12.1-Φ17 |

5 |

2.3 |

5X5 |

|||

|

Φ17.1-Φ22 |

6 |

±0.0180 |

2.8 |

6X6 |

||

|

Φ22.1-Φ30 |

8 |

3.3 |

±0.20 |

8X7 |

||

|

Φ30.1-Φ38 |

10 |

±0.0215 |

3.3 |

10X8 |

||

|

Φ38.1-Φ44 |

12 |

3.8 |

12X8 |

|||

|

Φ44.1-Φ50 |

14 |

4.3 |

14X9 |

|||

|

Φ50.1-Φ58 |

16 |

4.4 |

16X10 |

|||

|

Φ58.1-Φ65 |

18 |

4.4 |

18X11 |

|||

Outline dimension table

|

Outline dimension table |

mm |

|||||||

|

Model |

Common DL / D2 inner diameter size |

ΦD |

L |

LF |

LP |

F |

M |

Tightening torque (n.m) |

|

GLC-16X29 |

4-5-6-6.35 |

16 |

29 |

12.5 |

12 |

3 |

M2.5 |

0.8 |

|

GLC-20X33 |

5-6-6.35-7-8 |

20 |

33 |

14.1 |

12.7 |

3.8 |

M2.5 |

0.8 |

|

GLC-25X39 |

5-6-6.35-8-9-9.525-10-11-12 |

25 |

39 |

16.9 |

17.7 |

3.9 |

M3 |

1.2 |

|

GLC-32X45 |

5-6-8-9-9.525-10-11-12-12.7-14-15-16 |

32 |

45 |

20 |

20 |

4.5 |

M4 |

2.5 |

|

GLC-40X50 |

8-9-9.525-10-11-12-14-15-16-17-18-19 |

40 |

50 |

23 |

20.3 |

5.5 |

M5 |

5 |

|

GLC-44X46 |

8-9-9.525-10-11-12-14-15-16-17-18-19-20-22 |

44 |

46 |

20.7 |

18.4 |

7 |

M5 |

5 |

|

GLC-50X53 |

10-11-12.7-14-15-16-17-18-19-20-22-24 |

50 |

53 |

24.2 |

22.35 |

7.5 |

M6 |

8 |

|

GLC-50X58 |

10-11-12.7-14-15-16-17-18-19-20-22-24 |

50 |

58 |

26.5 |

22.35 |

6.3 |

M6 |

8 |

|

GLC-55X57 |

10-11-12.7-14-15-16-17-18-19-20-22-24-25-28 |

55 |

57 |

26.2 |

25.8 |

6.3 |

M6 |

8 |

|

GLC-63X71 |

14-15-16-17-18-19-20-22-24-25-28-30-32 |

63 |

71 |

32.8 |

26.2 |

7.8 |

M8 |

20 |

|

GLC-70X77 |

14-15-16-17-18-19-20-22-24-25-28-30-32-35-38 |

70 |

71 |

37 |

25 |

7.7 |

M8 |

20 |

Technical parameter

|

Technical parameter |

m m |

||||||||

| Model | Rated torque (N.m) |

Allowable eccentricity (mm) |

Allowable deflection angle (∠。) |

Allowable axial deviation (mm) | Allowable speed (RPM) | Static torsional stiffness (N.m/rad) |

Moment of inertia (N.m) | Coupling weight (g) |

|

| GLC-16X29 | 0.7 | 0.8 | 3 | ±0.2 | 9000 | 30 | 3.5X10-7 | 12 | |

| GLC-20X33 | 1..2 | 1.2 | 3 | ±0.2 | 7000 | 58 | 1.5X10-6 | 19 | |

| GLC-25X39 | 2 | 1.6 | 3 | ±0.2 | 6000 | 130 | 3.2X10-6 | 35 | |

| GLC-32X45 | 4.5 | 2 | 3 | ±0.2 | 4800 | 270 | 1.5X10-5 | 67 | |

| GLC40X50 | 9 | 2.4 | 3 | ±0.2 | 3600 | 520 | 4.2X10-5 | 114 | |

| GLC-44X46 | 12 | 2.5 | 3 | ±0.2 | 3500 | 800 | 4.5X10-5 | 140 | |

| GLC-50X53 | 19 | 2.6 | 3 | ±0.2 | 3000 | 800 | 1.0X10-4 | 190 | |

| GLC-50X58 | 19 | 3 | 3 | ±0.2 | 3000 | 800 | 1.1X10-4 | 215 | |

| GLC-55X57 | 25 | 3.2 | 3 | ±0.2 | 3000 | 900 | 1.3X10-5 | 260 | |

| GLC-63X71 | 33 | 3 | 3 | ±0.2 | 2550 | 1200 | 3.5X10-4 | 455 | |

| GLC -70X77 | 56 | 3.5 | 3 | ±0.2 | 2500 | 1260 | 4.1X10-4 | 520 | |

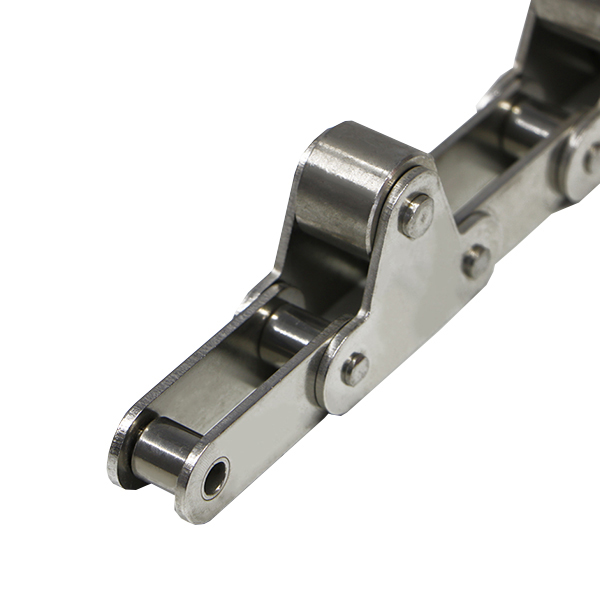

Oldham couplings are three-piece flexible shaft couplings that are used to connect driving and driven shafts in mechanical power transmission assemblies. Flexible shaft couplings are used to counter the inevitable misalignment that occurs between connected shafts and, in some cases, to absorb shock. Material: Uubs are in Aluminium, elastic body is in PA66.

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for Quality Inspection for Rm Couplings - Oldham Couplings, Body AL, Elastic PA66 – GOODLUCK , The product will supply to all over the world, such as: New Orleans, South Africa, Finland, All the imported machines effectively control and guarantee the machining precision for the items. Besides, we have a group of high-quality management personnels and professionals, who make the high-quality items and have the ability to develop new merchandise to expand our market home and abroad. We sincerely expect customers come for a blooming business for both of us.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.