Double Pitch Sprockets per Asian Standard

NK2040SB

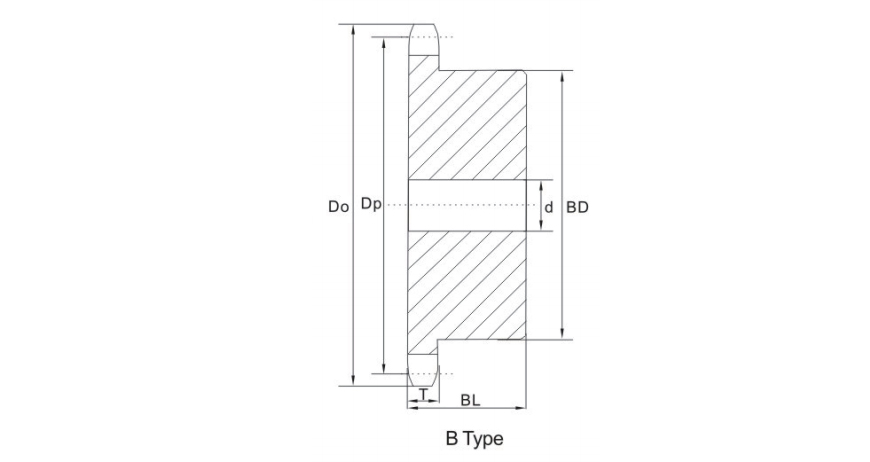

| SPROCKETS | mm |

| Tooth width (T) | 7.2 |

| CHAIN | mm |

| Pitch (P) | 25.4 |

| Internal width | 7.95 |

| Roller Φ (Dr) | 7.95 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

Wt kg |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK2040SB |

6 1/2 |

59 |

54.66 |

13 |

15 |

20 |

35 |

22 |

0.20 |

C45 Solid |

|

7 1/2 |

67 |

62.45 |

13 |

15 |

25 |

43 |

22 |

0.30 |

||

|

8 1/2 |

76 |

70.31 |

13 |

15 |

32 |

52 |

22 |

0.42 |

||

|

9 1/2 |

84 |

78.23 |

13 |

15 |

38 |

60 |

25 |

0.61 |

||

|

10 1/2 |

92 |

86.17 |

14 |

16 |

46 |

69 |

25 |

0.82 |

||

|

11 1/2 |

100 |

94.15 |

14 |

16 |

51 |

77 |

25 |

0.98 |

||

|

12 1/2 |

108 |

102.14 |

14 |

16 |

42 |

63 |

25 |

0.83 |

||

NK 2050SB

| SPROCKETS | mm |

| Tooth width (T) | 8.7 |

| CHAIN | mm |

| Pitch (P) | 31.75 |

| Internal width | 9.53 |

| Roller Φ (Dr) | 10.16 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

Wt kg |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK2050SB |

6 1/2 |

74 |

68.32 |

14 |

16 |

25 |

44 |

25 |

038 |

C45 Solid |

|

7 1/2 |

84 |

78.06 |

14 |

16 |

32 |

54 |

25 |

0.55 |

||

|

8 1/2 |

94 |

87.89 |

14 |

16 |

45 |

65 |

25 |

0-76 |

||

|

9 1/2 |

105 |

97.78 |

14 |

16 |

48 |

73 |

28 |

1-06 |

||

|

10 1/2 |

115 |

107,72 |

14 |

16 |

48 |

73 |

28 |

1.16 |

||

|

11 1/2 |

125 |

117.68 |

16 |

18 |

48 |

73 |

28 |

1.27 |

||

|

12 1/2 |

135 |

127.67 |

16 |

18 |

48 |

73 |

28 |

1.40 |

||

NK 2060SB

| SPROCKETS | mm |

| Tooth width (T) | 11.7 |

| CHAIN | mm |

| Pitch (P) | 38.10 |

| Internal width | 12.70 |

| Roller Φ (Dr) | 11.91 |

|

Type |

Teeth |

Do |

Dp |

Bored |

BD |

BL |

wt kg |

Material |

||

|

Stock |

Min |

Max |

||||||||

|

NK2060SB

|

6 1/2 |

88 |

81.98 |

14 |

16 |

32 |

53 |

32 |

0.73 |

C45 Solid

|

|

7 1/2 |

101 |

93.67 |

16 |

18 |

45 |

66 |

32 |

1.05 |

||

|

8 1/2 |

113 |

105.47 |

16 |

18 |

48 |

73 |

32 |

133 |

||

|

9 1/2 |

126 |

117.34 |

16 |

18 |

55 |

83 |

40 |

203 |

||

|

10 1/2 |

138 |

129.26 |

16 |

18 |

55 |

83 |

40 |

2.23 |

||

|

11 1/2 |

150 |

141.22 |

16 |

18 |

55 |

80 |

45 |

256 |

||

|

12 1/2 |

162 |

153.20 |

16 |

18 |

55 |

80 |

45 |

281 |

||

Double pitch conveyor chain sprockets are often are ideal for saving on space and have a longer wear life than standard sprockets. Suitable for long pitch chain, double pitch sprockets possess more teeth than a standard sprocket of the same pitch circle diameter and distribute wear evenly across the teeth. If your conveyor chain is compatible, double pitch sprockets are definitely worth considering.

Sprockets for double pitch roller chains are available in a single or double-toothed design. Single-toothed sprockets for double pitch roller chains have the same behaviour as standard sprockets for roller chains according to DIN 8187 (ISO 606). Due to the larger chain pitch of double pitch roller chains it is possible to increase durability by toothing modifications.

Standard roller type sprockets are the same outside diameter and width as the single-pitch equivalent just with a different tooth profile to allow proper seating of the chain. On even tooth-counts, these sprockets only engage with the chain on every other tooth because there are two teeth per pitch. On odd tooth counts, any given tooth is engaged only on every other revolution which of course increases the sprocket life.