SS Hollow Pin Chains in Short Pitch,or in Double Pitch Straight Plate with Small/Big Roller

|

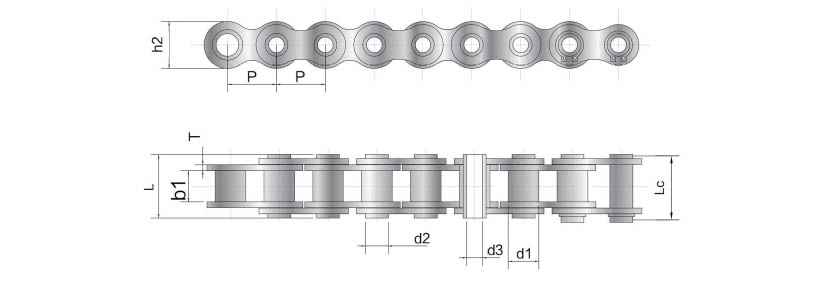

GL Chain No |

Pitch |

Roller Diameter |

Width Between Inner Plates |

Pin Diameter |

Pin Length |

Inner Plate Height |

Plate Thickness |

Ultimate Tensile Strength |

Weight Per Meter |

||

|

P |

d1 |

b1 |

d2 |

d3 |

L |

Lc |

h2 |

T |

Q |

Q. |

|

|

max |

min |

max |

max |

max |

max |

max |

max |

min |

|||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

KN |

Kg/m |

|

|

SS40HP |

12.700 |

7.95 |

7.85 |

5.94 |

4.00 |

16.60 |

17.50 |

12.00 |

1.50 |

7.70 |

0.54 |

|

SS08BHP |

12.700 |

8.51 |

7.75 |

6.32 |

4.50 |

16.80 |

17.60 |

12.15 |

1.60 |

7.80 |

0.52 |

|

SS50HP |

15.875 |

10.16 |

9.40 |

7.03 |

5.10 |

20.75 |

22.20 |

15.09 |

2.00 |

14.00 |

0.91 |

|

SS60HP |

19.050 |

11.91 |

12.70 |

8.31 |

6.00 |

26.85 |

26.80 |

18.00 |

2.42 |

16.80 |

1.29 |

|

SS80HP |

25.400 |

15.88 |

15.75 |

11.10 |

8.10 |

32.60 |

34.00 |

24.00 |

3.15 |

35.00 |

2.26 |

|

SSA2080HP |

50.800 |

15.88 |

15.75 |

11.10 |

8.010 |

32.60 |

34.00 |

24.00 |

3.15 |

29.60 |

1.60 |

|

SS10BHP |

15.875 |

10.16 |

9.65 |

7.01 |

5.10 |

19.60 |

20.50 |

14.85 |

1.70 |

11.90 |

0.96 |

|

SS12BHP |

19.050 |

12.07 |

11.68 |

8.02 |

6.00 |

22.60 |

23.90 |

16.50 |

1.85 |

16.52 |

1.09 |

|

SSHB38.1 |

38.100 |

20.00 |

8.00 |

8.00 |

5.30 |

19.60 |

20.70 |

17.30 |

2.00 |

19.60 |

0.98 |

|

SSHP50.8 |

50.800 |

26.00 |

15.88 |

20.00 |

14.30 |

41.00 |

42.20 |

38.10 |

4.80 |

70.00 |

5.32 |

|

SSHB50.8 |

50.800 |

30.00 |

10.50 |

11.40 |

8.20 |

27.40 |

28.60 |

26.00 |

3.10 |

35.00 |

2.56 |

Hollow pin chain

|

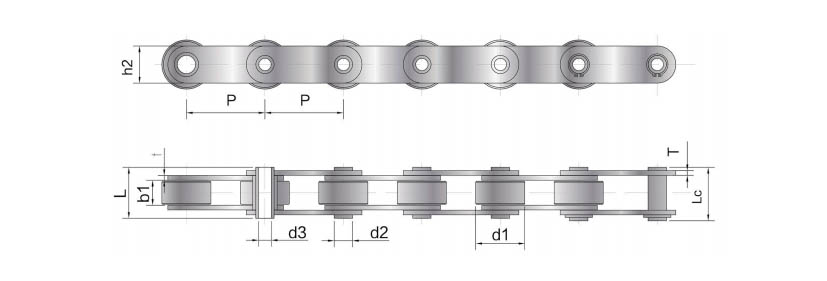

GL Chain No

|

Pitch |

Roller Diameter |

Width Between Inner Plates |

Pin Diameter |

Pin Length |

Inner Plate Height |

Plate Thickness |

Ultimate Tensile Strength |

Weight Per Meter |

||

|

P |

d1 |

b1 |

d2 |

d3 |

L |

Lc |

h2 |

T |

Q |

q. |

|

|

max |

min |

max |

max |

max |

max |

max |

max |

min |

|||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

KN |

Kg/m |

|

|

SSC2040HP |

25.400 |

7.95 |

7.85 |

5.94 |

4.00 |

16.60 |

17.50 |

12.00 |

1.50 |

7.7/1750 |

0.46 |

|

SSC2050HP |

31.750 |

10.16 |

9.40 |

7.03 |

5.10 |

20.75 |

22.20 |

15.00 |

2.00 |

14.28/3245.2 |

0.76 |

|

SSC2060HP |

38.100 |

11.91 |

12.70 |

8.31 |

6.00 |

25.85 |

26.80 |

18.00 |

2.42 |

16.8/3818.5 |

1.02 |

|

SSC2080HP |

50.800 |

15.88 |

15.75 |

11.10 |

8.10 |

32.60 |

34.00 |

24.00 |

3.15 |

35/7954.8 |

1.81 |

|

SSC2060H-HP |

38.100 |

11.91 |

12.70 |

8.31 |

6.00 |

29.25 |

30.50 |

18.00 |

3.15 |

24/5455 |

1.29 |

|

SSC40HP |

12.700 |

7.95 |

7.85 |

5.94 |

4.00 |

16.60 |

17.50 |

12.00 |

1.50 |

7.7/1750 |

0.64 |

|

SSC50HP |

15.875 |

10.16 |

9.40 |

7.03 |

5.10 |

20.75 |

22.20 |

15.09 |

2.00 |

14/3181.5 |

1.05 |

|

SSC60HP |

19.050 |

11.91 |

12.70 |

8.31 |

6.00 |

25.85 |

26.80 |

18.00 |

2.42 |

16.8/3818.5 |

1.52 |

|

SSC80HP |

25.400 |

15.88 |

15.75 |

11.10 |

8.10 |

34.00 |

33.80 |

24.00 |

3.15 |

35/7954.8 |

2.63 |

|

SSC08BHP |

12.700 |

8.51 |

7.75 |

6.32 |

4.50 |

16.80 |

17.60 |

12.15 |

1.6 |

7.7/1750 |

0.62 |

|

GL Chain No

|

Pitch |

Roller Diameter |

Width Between Inner Plates |

Pin Diameter |

Pin Length |

Inner Plate Height |

Plate Thickness |

Ultimate Tensile Strength |

Weight Per Meter |

||

|

P |

d1 |

b1 |

d2 |

d3 |

L |

Lc |

h2 |

T |

Q |

q. |

|

|

max |

min |

max |

max |

max |

max |

max |

max |

min |

|||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

KN |

Kg/m |

|

|

SSC2040HP |

25.400 |

15.88 |

7.85 |

5.94 |

4.00 |

16.60 |

17.50 |

12.00 |

1.50 |

7.7 |

0.78 |

|

SSC2052HP |

31.750 |

19.05 |

9.53 |

7.03 |

5.10 |

20.75 |

22.20 |

15.00 |

2.00 |

14.28 |

1.25 |

|

SSC2062HP |

38.100 |

22.23 |

12.70 |

8.31 |

6.00 |

25.85 |

26.80 |

18.00 |

2.42 |

16.8 |

1.72 |

|

SSC2082HP |

50.800 |

28.58 |

15.75 |

11.10 |

8.10 |

32.60 |

34.00 |

24.00 |

3.15 |

35 |

2.82 |

|

SSC2042H-HP |

25.400 |

15.88 | 7.85 | 5.94 |

4.00 |

19.20 | 20.00 |

12.00 |

2.00 |

7.7 |

0.95 |

|

SSC2052H-HP |

31.750 |

19.05 | 9.53 | 7.03 |

5.10 |

22.60 | 24.00 |

15.00 |

2.42 | 14.26 | 1.44 |

|

SSC2062H-HP |

38.100 |

22.23 | 12.70 | 8.31 |

6.00 |

29.25 | 30.50 |

18.09 |

3.15 |

16.80 |

1.99 |

|

SSC2082H-HP |

50.800 |

28.58 | 15.75 | 11.10 |

8.10 |

35.70 | 37.00 |

24.00 |

4.00 | 35.00 |

3.44 |

|

SSHP50.8 |

50.800 |

26.00 |

15.88 |

20.00 |

14.30 |

41.00 |

42.20 | 38.10 | 4.80 |

70.00 |

5.32 |

GL stainless steel hollow pin roller chain is manufactured in accordance to ISO 606, ANSI,and DIN8187 manufacturing standards. Our hollow pin stainless steel chain is manufactured from high-quality 304-grade stainless steel. 304SS is a highly anti-corrosive material with a very low magnetic pull, its also capable of operating in very low to very high temperatures without degrading the working and performance capacity of the chain. The hollow pin design makes the chain capable of having attachments fastened through its holes (hollow pins) for conveying and elevating applications.